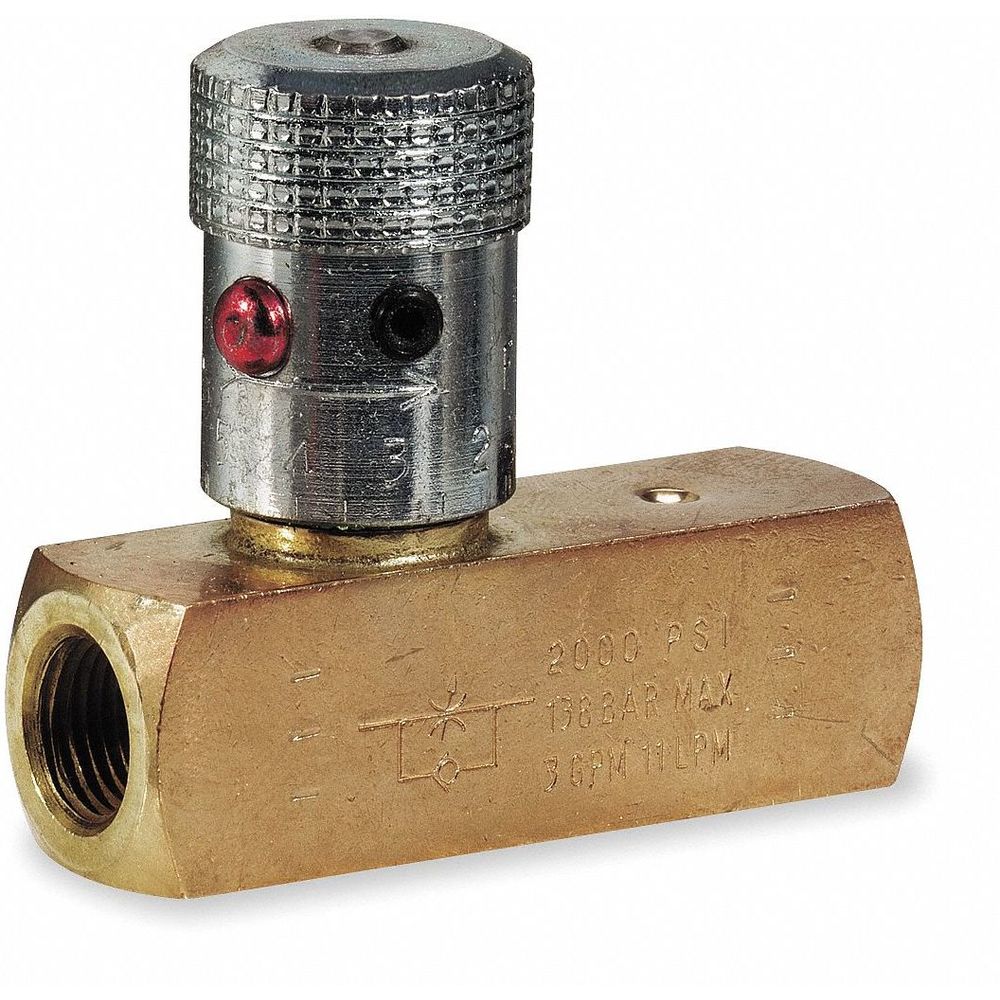

PARKER F Series,In Line Flow Control Valves

Parker F Series in-line flow control valves are used in hydraulic systems, pneumatic equipment, industrial machinery and automation systems. They are ideal for regulating fluid flow, ensuring precise control and enhanced system performance. These Parker flow control valves require flow rate adj...ustments to maintain efficiency, safety and optimal performance.Read more

Filter

| Style | Model | Body Material | Valve Type | Max. Pressure | Flow Rate | Flow Range | Max. Flow Rate | Seal Material | Type | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | F1200B | - | - | - | - | - | - | - | - | €323.28 | RFQ

|

| B | F600B | Brass | Brass | 2000 psi | 8 GPM | 8 GPM | - | Nitrile | - | €141.28 | |

| C | F400B | Brass | Brass | 2000 psi | 5 GPM | 5 GPM | - | Nitrile | - | €108.94 | |

| D | F800B | Brass | Hydraulic Flow Control Valve | - | 15 GPM | - | 15 GPM | Nitrile | - | €200.73 | |

| C | F400S | Steel | Steel | 5000 psi | 5 GPM | 5 GPM | - | Nitrile | - | €93.76 | |

| E | F800S | Steel | - | - | - | - | - | Nitrile | Steel | €156.95 | |

| C | F600S | Steel | Steel | 5000 psi | 8 GPM | 8 GPM | - | Nitrile | - | €112.03 | |

| C | F1200S | Steel | Steel | 3000 psi | 25 GPM | 25 GPM | - | Nitrile | - | €233.18 |

Working Mechanism

- These Parker flow control valves regulate flow by adjusting a tapered needle orifice.

- They then control flow rate by turning the adjustment screw.

- Then the flow is modified by changing the opening between the needle and valve seat.

- This results in precise fluid flow control in hydraulic and pneumatic systems.

Features

- They offer operating temperatures ranging from -40 to 205 degrees C, ensuring versatility in extreme environments.

- These Parker flow control valves are manually actuated for precise control over fluid flow.

- They can function as flow control valves and come with NPT, SAE, BSPT and BSPP connections for efficient operations.

- These Parker flow control valves have brass / steel / stainless steel body for durability and compatibility.

- They use nitrile and fluorocarbon seals for enhanced reliability and performance.

Frequently Asked Questions

How do I clean and maintain Parker flow control valves?

- Ensure that the valve is disconnected from the system.

- Clean with a soft cloth, removing any dirt or debris.

- Apply a recommended lubricant to moving parts.

- Regularly check for wear, damage or leaks.

- Reconnect and test for proper functionality.

What factors should I consider while choosing in-line flow control valves?

- Determine the required flow rate for your application.

- Ensure that the valve can handle the system's pressure.

- Choose between needle, ball or globe valves based on control precision.

- Select a compatible material for your fluid.

- Match the valve size to your piping.

Does Raptor Supplies offer any directional control valves?

Yes, customers looking for directional control valves from Parker can opt for D1VW Series control valves.

We are here to help!

Looking for a part not listed here?

Explore More

- KEYSHAFT

- SCOTCH

- MSI

- PAULSON

- SNR

- LED Wall Packs

- Antifatigue Mats

- Safety Banners and Posters

- Straight Blade Connectors

- Drum Covers

- FS1500 Series Fiberglass Step Ladders - LOUISVILLE

- Rush Safety Glasses - BOLLE SAFETY

- 11-651 Hyflex Medium Duty Cut Resistant Industrial Protective Gloves - ANSELL

- Circulation Heaters - TEMPCO

- NC Spotting Drills, 120 Degrees Point Angle - KEO

- Compressor Repair Kit Gauge - DIVERSITECH

- R Series Rigid Couplings - DIXON

- 8010 Series, Nipple - PARKER

- Vinyl, Safety Sign, 7 Inch Width - CONDOR

- B634 Series Single Channel Adjustable Braces - COOPER B-LINE