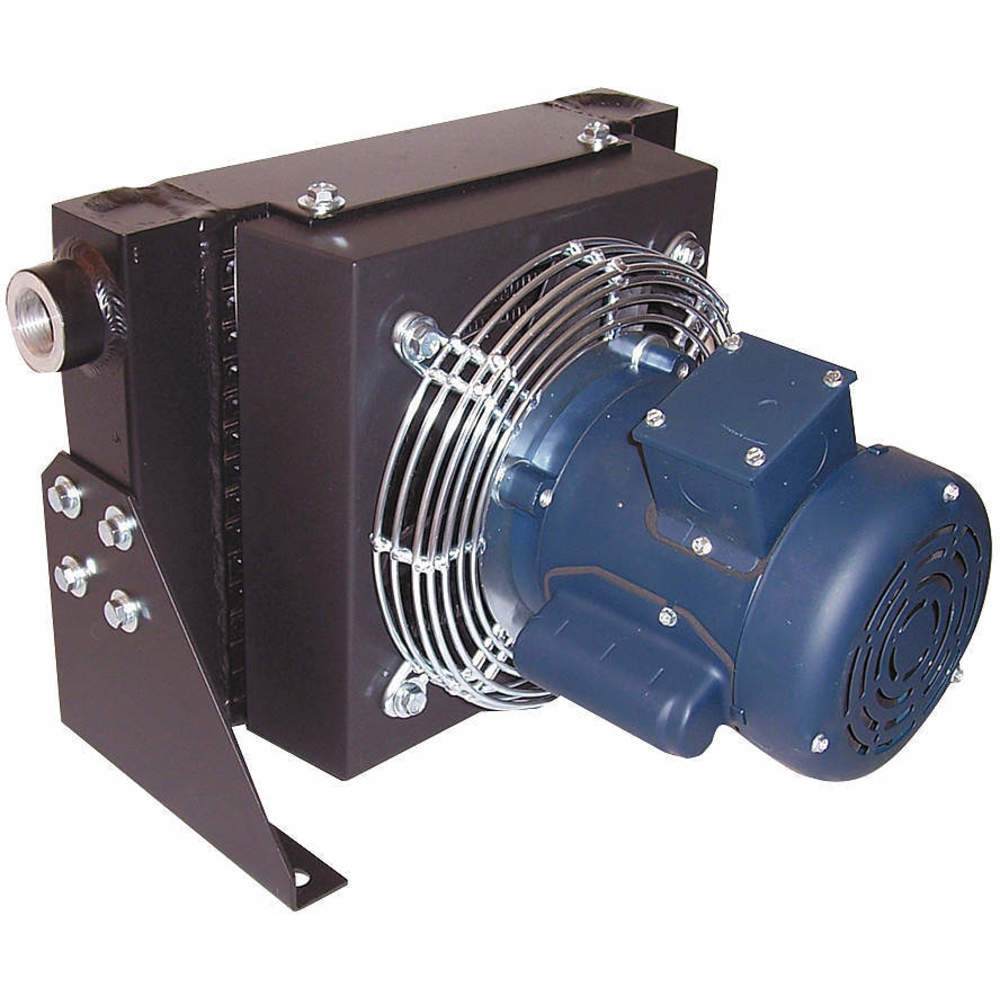

AKG CC600-1 Air Aftercooler Max Hp 125 785 Cfm

Get it by Tuesday, Jun 17

Payment

Get it by Tuesday, Jun 17

Payment

| Item | Air Cooled Aftercooler |

| Depth | 18.74" |

| Height | 23.19" |

| Max. Amps | 12.8/6.4A |

| Max. Flow Cfm @ 100 Psi | 785 CFM |

| Max. Pressure | 250 psi |

| Max. Temp. | 350°F |

| Min. Pressure | 60 psi |

| Tube Material | Aluminum |

| Voltage | 115/230V |

| Width | 30.31" |

| Air Inlet Size | 2" |

| Air Inlet Type | NPT |

| Air Outlet Connection Type | NPT |

| Air Outlet Size | 2" |

| Construction | Aluminum |

| Cooling Method | Air |

| Current Rating | 6.4A |

| Features | Reduced Air Slide Fouling |

| Fin Material | Aluminum |

| For Use With | Rotary Air Compressor |

| Frequency | 60 Hz |

| Includes | Mounting Legs |

| Junction Box Design | Single Point Electrical |

| Maximum Air Flow | 785 CFM |

| Maximum Compressor Output Power | 100 hp |

| Maximum Fan Horsepower | 1 hp |

| Maximum Operating Pressure | 250 psi |

| Maximum Operating Temperature | 350°F |

| Minimum Operating Pressure | 60 psi |

| Overall Depth | 18 11/16" |

| Overall Height | 23 3/16" |

| Overall Width | 30 1/4" |

| Phase | Single |

| Shell Material | Steel |

| Standards | CSA CERTIFIED, UL LISTED |

| Ship weight (kg) | 73.35 |

| Ship height (cm) | 58.9 |

| Ship length (cm) | 47.47 |

| Ship width (cm) | 76.84 |

| HS code | 8419505000 |

| Country of Origin | US |

AKG CC600-1 air aftercooler is installed to cool the compressed air exiting a compressor before it enters the engine's intake manifold or other downstream systems. It is useful in the automotive, marine, aerospace and manufacturing industries. This cooling unit is used in internal combustion engines, gas turbines and air compression systems.

A. In turbocharged engines, it reduces the temperature of the compressed air generated by the turbocharger before it enters the engine's intake manifold. This cooler & denser air allows more efficient combustion, resulting in increased power output while reducing the risk of engine knock or detonation.

A. Air aftercoolers provide a continuous cooling effect by reducing the temperature of the intake air, resulting in improved engine efficiency and performance. In contrast, water injection and nitrous oxide systems provide temporary power boosts by introducing additional substances into the combustion chamber.

A. To prevent icing or condensation buildup in air aftercoolers, ensure that the compressed air entering the aftercooler is adequately dried and free of moisture which can be done by installing moisture separators or desiccant dryers upstream of the aftercooler. Additionally, insulate any exposed sections of the aftercooler to minimise temperature fluctuations and reduce the risk of condensation forming on the cooling surfaces.

A. To extend the lifespan of an air aftercooler, adhere to recommended maintenance intervals and procedures, including regular cleaning and inspection. Avoid operating the aftercooler under extreme conditions or beyond its rated capacity, as this can accelerate wear and reduce reliability. Additionally, protect the aftercooler from physical damage and corrosion by installing guards or shields as needed. Lastly, address any issues promptly to prevent further damage or deterioration.

| Product | Model | Depth | Height | Max. Amps | Max. Temp. | Voltage | Width | Price | |

|---|---|---|---|---|---|---|---|---|---|

|

CC100-1 | 14.72" | 12.64" | 5.2/2.6 | 350 F | 115/230 | 15.94" | €3,024.00 | |

|

CC200-1 | 15.59" | 16.3" | 7/3.5 | 350 F | 115/230 | 19.88" | €3,619.80 | |

|

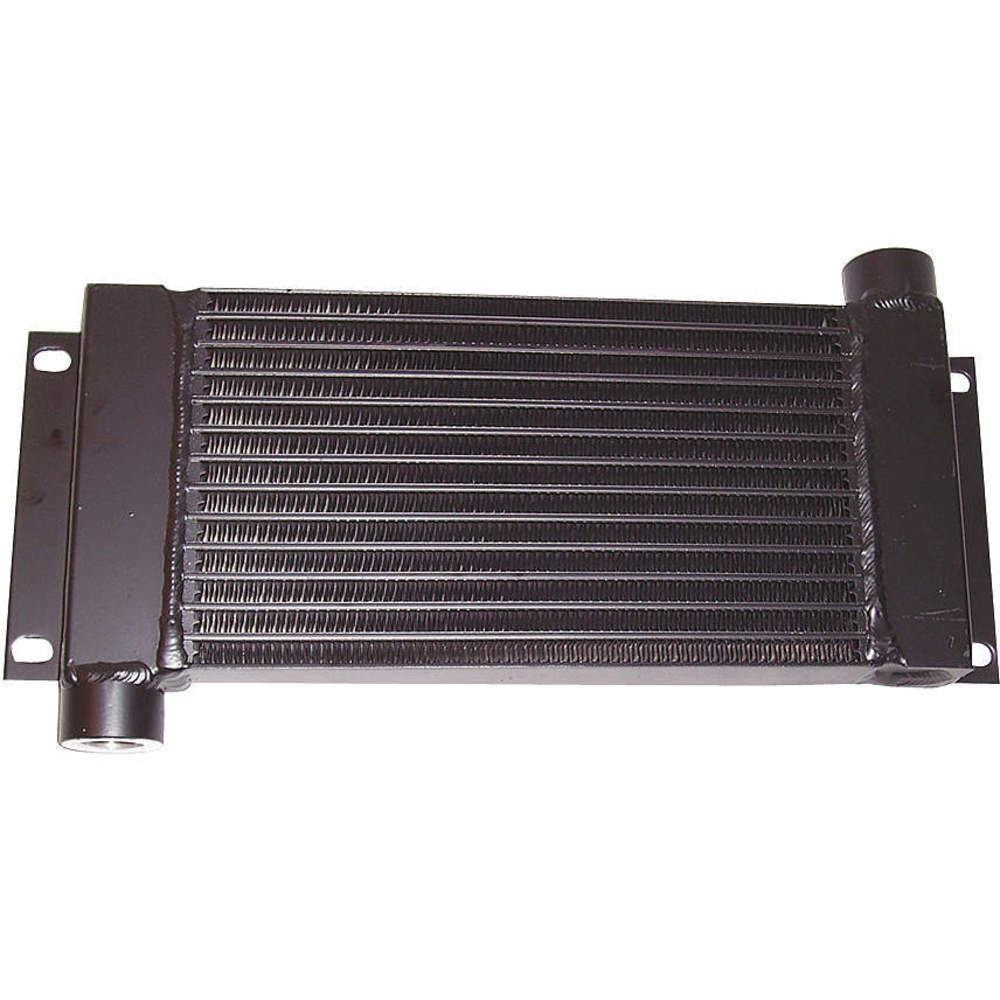

C-1835BG | 1.77" | 5.55" | - | 400 F | - | 15.94" | €384.62 | |

|

C-3560BG | 1.77" | 6.77" | - | 400 F | - | 15.94" | €429.59 | |

|

C-70100BG | 1.77" | 9.17" | - | 400 F | - | 17.91" | €529.45 | |

|

CC1600-3 | 24.76" | 35.9" | 13.2/6.6 | 350 F | 230/460 | 40.94" | €17,209.80 | |

|

CC2500-3 | 30.28" | 44.25" | 19.6/9.8 | 350 F | 230/460 | 48.82" | €23,909.40 |

Contact your account manager right away to get personal advice.

We're available Monday through Friday, from 07:30 until 17:00.