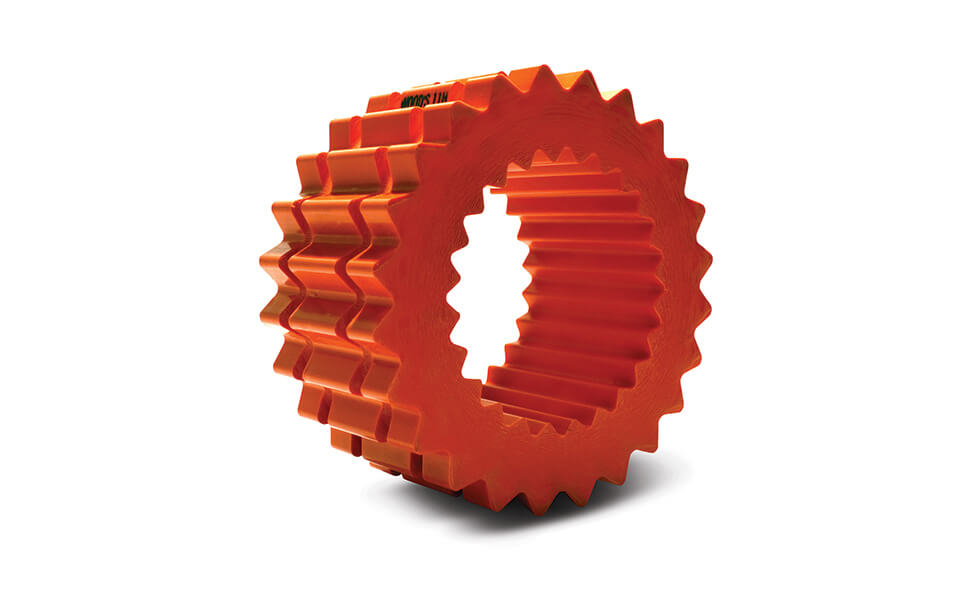

TB WOODS Sure Flex Coupling Sleeves

TB Wood's Sure-Flex Plus sleeve couplings protect fans, blowers, pumps, electric motors, compressors, mixers and conveyors against misalignments, vibrations and shock loads.

| Style | Model | Coupling Size | Outside Dia. | Max. Speed | Rated Torque | Hp Rating @ 100 Rpm | Max. Angular Gap Misalignment | Operating Temp. | Hp Rating @ 1200 Rpm | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 3JS | 3 | 1 7/8" | 9200 RPM | 78 lbs.-in. | 3/25 hp | 0.035" | -30°F to +275°F | 1 49/100 hp | €12.28 | |

| B | 3JN | 3 | 1 7/8" | 9200 RPM | 78 lbs.-in. | 3/25 hp | 0.035" | 0°F to +200°F | 1 49/100 hp | €12.28 | |

| B | 3J | 3 | 1 7/8" | 9200 RPM | 78 lbs.-in. | 3/25 hp | 0.035" | -30°F to +275°F | 1 49/100 hp | €9.19 | |

| A | 3JNS | 3 | 1 7/8" | 9200 RPM | 78 lbs.-in. | 3/25 hp | 0.035" | 0°F to +200°F | 1 49/100 hp | €15.77 | |

| C | 4N | 4 | 2.312" | 7600 RPM | 156 lbs.-in. | 1/4 hp | 0.043" | 0°F to +200°F | 2 97/100 hp | €65.72 | |

| B | 4J | 4 | 2.312" | 7600 RPM | 156 lbs.-in. | 1/4 hp | 0.043" | -30°F to +275°F | 2 97/100 hp | €13.13 | |

| B | 4JN | 4 | 2.312" | 7600 RPM | 156 lbs.-in. | 1/4 hp | 0.043" | 0°F to +200°F | 2 97/100 hp | €17.51 | |

| A | 4JS | 4 | 2.312" | 7600 RPM | 156 lbs.-in. | 1/4 hp | 0.043" | -30°F to +275°F | 2 97/100 hp | €17.51 | |

| A | 4JNS | 4 | 2.312" | 7600 RPM | 156 lbs.-in. | 1/4 hp | 0.043" | 0°F to +200°F | 2 97/100 hp | €21.04 | |

| C | 4 | 4 | 2.312" | 7600 RPM | - | 1/4 hp | 0.043" | -30°F to +275°F | 2 97/100 hp | €65.26 | |

| B | 5JN | 5 | 2.938" | 7600 RPM | 312 lbs.-in. | 1/2 hp | 0.056" | 0°F to +200°F | 5 47/50 hp | €30.67 | |

| B | 5J | 5 | 2.938" | 7600 RPM | 312 lbs.-in. | 1/2 hp | 0.056" | -30°F to +275°F | 5 47/50 hp | €26.28 | |

| C | 5N | 5 | 2.938" | 7600 RPM | 312 lbs.-in. | 1/2 hp | 0.056" | 0°F to +200°F | 5 47/50 hp | €74.46 | |

| C | 5 | 5 | 2.938" | 7600 RPM | - | 1/2 hp | 0.056" | -30°F to +275°F | 5 47/50 hp | €54.76 | |

| A | 5JNS | 5 | 2.938" | 7600 RPM | 312 lbs.-in. | 1/2 hp | 0.056" | 0°F to +200°F | 5 47/50 hp | €35.05 | |

| A | 5JS | 5 | 2.938" | 7600 RPM | 312 lbs.-in. | 1/2 hp | 0.056" | -30°F to +275°F | 5 47/50 hp | €30.67 | |

| D | 6H | 6 | 3 3/4" | 6000 RPM | 1800 lbs.-in. | 2 9/10 hp | 0.016" | -65°F to +250°F | 34 27/100 hp | €162.95 | |

| E | 6HS | 6 | 3 3/4" | 6000 RPM | 1800 lbs.-in. | 2 9/10 hp | 0.016" | -65°F to +250°F | 34 27/100 hp | €183.13 | |

| B | 6J | 6 | 3 3/4" | 6000 RPM | 585 lbs.-in. | 93/100 hp | 0.07" | -30°F to +275°F | 11 7/50 hp | €39.11 | |

| A | 6JNS | 6 | 3 3/4" | 6000 RPM | 585 lbs.-in. | 93/100 hp | 0.07" | 0°F to +200°F | 11 7/50 hp | €52.55 | |

| C | 6N | 6 | 3 3/4" | 6000 RPM | 585 lbs.-in. | 93/100 hp | 0.07" | 0°F to +200°F | 11 7/50 hp | €83.23 | |

| C | 6 | 6 | 3 3/4" | 6000 RPM | - | 93/100 hp | 0.07" | -30°F to +275°F | 11 7/50 hp | €69.55 | |

| B | 6JN | 6 | 3 3/4" | 6000 RPM | 585 lbs.-in. | 93/100 hp | 0.07" | 0°F to +200°F | 11 7/50 hp | €48.18 | |

| A | 6JS | 6 | 3 3/4" | 6000 RPM | 585 lbs.-in. | 93/100 hp | 0.07" | -30°F to +275°F | 11 7/50 hp | €48.18 | |

| B | 7J | 7 | 4.344" | 5250 RPM | 940 lbs.-in. | 1 1/2 hp | 0.081" | -30°F to +275°F | 17 9/10 hp | €56.96 | |

| C | 7N | 7 | 4.344" | 5250 RPM | 940 lbs.-in. | 1 1/2 hp | 0.081" | 0°F to +200°F | 17 9/10 hp | €100.77 | |

| A | 7JNS | 7 | 4.344" | 5250 RPM | 940 lbs.-in. | 1 1/2 hp | 0.081" | 0°F to +200°F | 17 9/10 hp | €70.09 | |

| E | 7HS | 7 | 4.344" | 5250 RPM | 2875 lbs.-in. | 4 3/5 hp | 0.02" | -65°F to +250°F | 54 37/50 hp | €250.68 | |

| D | 7H | 7 | 4.344" | 5250 RPM | 2875 lbs.-in. | 4 3/5 hp | 0.02" | -65°F to +250°F | 54 37/50 hp | €249.13 | |

| A | 7JS | 7 | 4.344" | 5250 RPM | 940 lbs.-in. | 1 1/2 hp | 0.081" | -30°F to +275°F | 17 9/10 hp | €58.27 | |

| C | 7 | 7 | 4.344" | 5250 RPM | - | 1 1/2 hp | 0.081" | -30°F to +275°F | 17 9/10 hp | €109.74 | |

| B | 7JN | 7 | 4.344" | 5250 RPM | 940 lbs.-in. | 1 1/2 hp | 0.081" | 0°F to +200°F | 17 9/10 hp | €65.72 | |

| D | 8H | 8 | 5.062" | 4500 RPM | 4530 lbs.-in. | 7 1/5 hp | 0.025" | -65°F to +250°F | 86 1/4 hp | €272.67 | |

| C | 8 | 8 | 5.062" | 4500 RPM | - | 2 3/10 hp | 0.094" | -30°F to +275°F | 28 2/25 hp | €147.94 | |

| B | 8J | 8 | 5.062" | 4500 RPM | 1475 lbs.-in. | 2 3/10 hp | 0.094" | -30°F to +275°F | 28 2/25 hp | €74.46 | |

| A | 8JNS | 8 | 5.062" | 4500 RPM | 1475 lbs.-in. | 2 3/10 hp | 0.094" | 0°F to +200°F | 28 2/25 hp | €92.00 | |

| B | 8JN | 8 | 5.062" | 4500 RPM | 1475 lbs.-in. | 2 3/10 hp | 0.094" | 0°F to +200°F | 28 2/25 hp | €87.60 | |

| A | 8JS | 8 | 5.062" | 4500 RPM | 1475 lbs.-in. | 2 3/10 hp | 0.094" | -30°F to +275°F | 28 2/25 hp | €78.86 | |

| C | 8N | 8 | 5.062" | 4500 RPM | 1475 lbs.-in. | 2 3/10 hp | 0.094" | 0°F to +200°F | 28 2/25 hp | €157.69 | |

| E | 8HS | 8 | 5.062" | 4500 RPM | 4530 lbs.-in. | 7 1/5 hp | 0.025" | -65°F to +250°F | 86 1/4 hp | €257.06 | |

| B | 9J | 9 | 6" | 3750 RPM | 2340 lbs.-in. | 3 7/10 hp | 0.109" | -30°F to +275°F | 44 11/20 hp | €84.77 | |

| C | 9 | 9 | 6" | 3750 RPM | - | 3 7/10 hp | 0.109" | -30°F to +275°F | 44 11/20 hp | €215.99 | |

| E | 9HS | 9 | 6" | 3750 RPM | 7200 lbs.-in. | 11 hp | 0.028" | -65°F to +250°F | 137 9/100 hp | €324.40 | |

| C | 9N | 9 | 6" | 3750 RPM | 2340 lbs.-in. | 3 7/10 hp | 0.109" | 0°F to +200°F | 44 11/20 hp | €183.99 | |

| D | 9H | 9 | 6" | 3750 RPM | 7200 lbs.-in. | 11 hp | 0.028" | -65°F to +250°F | 137 9/100 hp | €363.59 | |

| A | 9JS | 9 | 6" | 3750 RPM | 2340 lbs.-in. | 3 7/10 hp | 0.109" | -30°F to +275°F | 44 11/20 hp | €84.52 | |

| C | 10N | 10 | 7.062" | 3600 RPM | 3735 lbs.-in. | 5 9/10 hp | 0.128" | 0°F to +200°F | 71 11/100 hp | €258.46 | |

| D | 10H | 10 | 7.062" | 3600 RPM | 11350 lbs.-in. | 18 hp | 0.032" | -65°F to +250°F | 216 1/10 hp | €416.74 | |

| B | 10J | 10 | 7.062" | 3600 RPM | 3735 lbs.-in. | 5 9/10 hp | 0.128" | -30°F to +275°F | 71 11/100 hp | €122.64 | |

| E | 10HS | 10 | 7.062" | 3600 RPM | 11350 lbs.-in. | 18 hp | 0.032" | -65°F to +250°F | 216 1/100 hp | €457.03 | |

| A | 10JS | 10 | 7.062" | 3600 RPM | 3735 lbs.-in. | 5 9/10 hp | 0.128" | -30°F to +275°F | 71 11/100 hp | €131.42 | |

| C | 11N | 11 | 8.188" | 3600 RPM | 5890 lbs.-in. | 9 2/5 hp | 0.151" | 0°F to +200°F | 112 3/20 hp | €459.97 | |

| E | 11HS | 11 | 8.188" | 3600 RPM | 18000 lbs.-in. | 29 hp | 0.037" | -65°F to +250°F | 342 18/25 hp | €860.52 | |

| C | 11 | 11 | 8.188" | 3600 RPM | - | 9 2/5 hp | 0.151" | -30°F to +275°F | 112 3/20 hp | €380.75 | |

| D | 11H | 11 | 8.188" | 3600 RPM | 18000 lbs.-in. | 29 hp | 0.037" | -65°F to +250°F | 342 18/25 hp | €691.46 | |

| C | 12N | 12 | 9.562" | 2800 RPM | 1028 N-m | 15 hp | 0.175" | - | - | €517.33 | RFQ

|

| D | 12H | 12 | 9.562" | 2800 RPM | 1028 N-m | 50 hp | 0.042" | - | - | €1,178.41 | RFQ

|

| E | 12HS | 12 | 9.562" | 2800 RPM | 1028 N-m | 50 hp | 0.042" | - | - | €925.65 | |

| C | 12 | 12 | 9.562" | 2800 RPM | 1028 N-m | 15 hp | 0.175" | - | - | - | RFQ

|

| E | 13HS | 13 | 11.187" | 2400 RPM | 1028 N-m | 75 hp | 0.05" | - | - | €1,536.65 | |

| C | 13 | 13 | 11.187" | 2400 RPM | 1028 N-m | 23 hp | 0.195" | - | - | - | RFQ

|

Sure Flex Coupling Sleeves

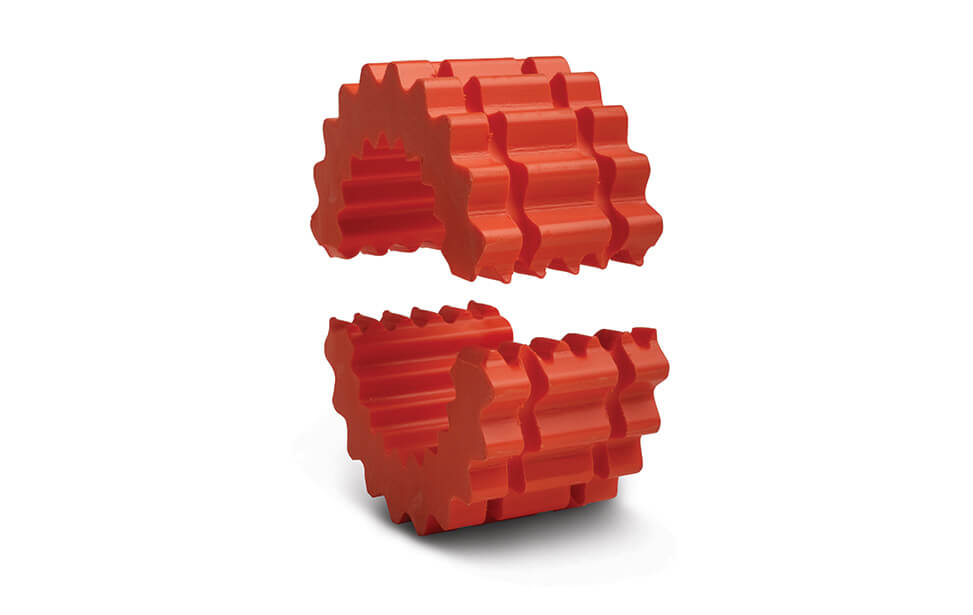

Sure-Flex Plus couplings use EPDM, neoprene, Hytrel and urethane made flexible elastomer sleeves for transmitting torque and accommodating shaft misalignments. Sure-Flex Plus couplings provide excellent torsional flexibility owing to their 4-way flexing action for absorbing all types of misalignments, shocks, vibrations & end floats. The uniquely designed teeth of these Sure-Flex Plus couplings allow the accommodation of angular misalignments without wear, which can be achieved with callipers or a scale. These sleeve couplings absorb parallel misalignments without wear and noticeable energy loss. The lateral flexibility of these sleeve couplings reduces radial bearing loads associated with the parallel misalignment.

Sure-Flex Plus couplings can be used in applications with limited axial shaft movements. These couplings offer 30% increased torque rating for ensuring minimum required maintenance and have over 3x longer service life than most competitive couplings. Sure-Flex Plus sleeves can be entirely interchanged with existing flanges, thereby delivering performance improvement.

Uses

TB Wood's Sure-Flex Plus sleeve couplings are used to protect pumps, fans / blowers, compressors, mixers, electric motors and conveyors against vibrations, misalignments and shock loads.

Features

- TB Wood's Sure-Flex Plus sleeve couplings are made of EPDM / Hytrel / neoprene to provide excellent adhesion and resistance from damage caused by flexing or twisting.

- These couplings provide quick & secure installation without any gaskets, bolts,seals or covers.

- TB Wood's Sure-Flex Plus sleeve couplings do not require any lubrication, thus minimising maintenance cost.

- These Sure-Flex Plus sleeve couplings are capable of driving equipment (pumps) with speeds ranging between 1500 and 9200 rpm.

- TB Wood's Sure-Flex Plus sleeve couplings can be operated at temperatures ranging from -65 to 275 degrees F.

- They offer torque up to 72480 inch-lb.

- These sleeve couplings come with standard AGMA keyways and clearance fits.

Standards and Approvals

TB Wood's Sure-Flex Plus sleeve couplings comply with EN 1127-1:2007, EN 13463-1:2009 and EN 13463-5:2003 standards to deliver high-quality services.

Installation

Sure-Flex Plus couplings can be installed quickly and securely, owing to their simple design having no bolts, gaskets, covers or seals. Alignment can be checked on the precision-machined flanges using only a straightedge and callipers. No special tools are needed for installation, alignment or removal.

Frequently Asked Questions

Is a coupling a permanent joint?

A coupling is a mechanical device used for holding two rotating shafts together. It is a permanent joint, unlike a clutch that can be disengaged when the operator requires it to. With the help of couplings, you can join two shafts that are colinear, intersecting or parallel.

Where are couplings used?

Couplings are mechanical components used in the automobile, electrical and aerospace industries for connecting two inline shafts, allowing one shaft to drive the other at the same speed. A coupling can be flexible or rigid, allowing varying degrees of radial, angular and axial misalignment between the shafts.

Which is a sleeve coupling?

A sleeve coupling is a simple rigid coupling consisting of a cylindrical sleeve keyed to the shafts that need to be connected. The sleeve transfers the torque from one shaft to the other without any loss.

We are here to help!

Looking for a part not listed here?

Explore More

- EAGLE

- KEYSHAFT

- SLICK LOCKS

- PETERSEN MFG.

- ULTRA-DEX USA

- Box I-Beam and Torpedo Levels

- Air Cylinder Speed Controls

- Flatware Dispensers

- Nesting Bins

- Dock Barricades

- Disposable Coveralls - LAKELAND

- Leather Gloves, Cowhide, Premium, Full Finger, Wing Thumb, Blue/Yellow - CONDOR

- Reducer, Copper, Press X Press Connection - VIEGA PROPRESS

- Acid Resistant Flare Nozzles - LOC-LINE

- Powerline X9500 Gas Springs - ASSOCIATED SPRING RAYMOND

- Caulk Gun, Ratchet Rod - WESTWARD

- Liqui-Fit Plug-In Tees - DIXON

- High Performance Roughing/Finishing Bright Finish Carbide Corne Radius End Mills - GRAINGER

- LF3110 Series Dielectric Unions - WATTS

- R823P BlueFire ZA Fine Grit Cloth Wide Belts - NORTON ABRASIVES