Pneumatic Vibrators

Pneumatic vibrators are industrial vibrators that generate vibration using compressed air. They are used to move a wide range of materials like powders, granules, pellets & bulk solids

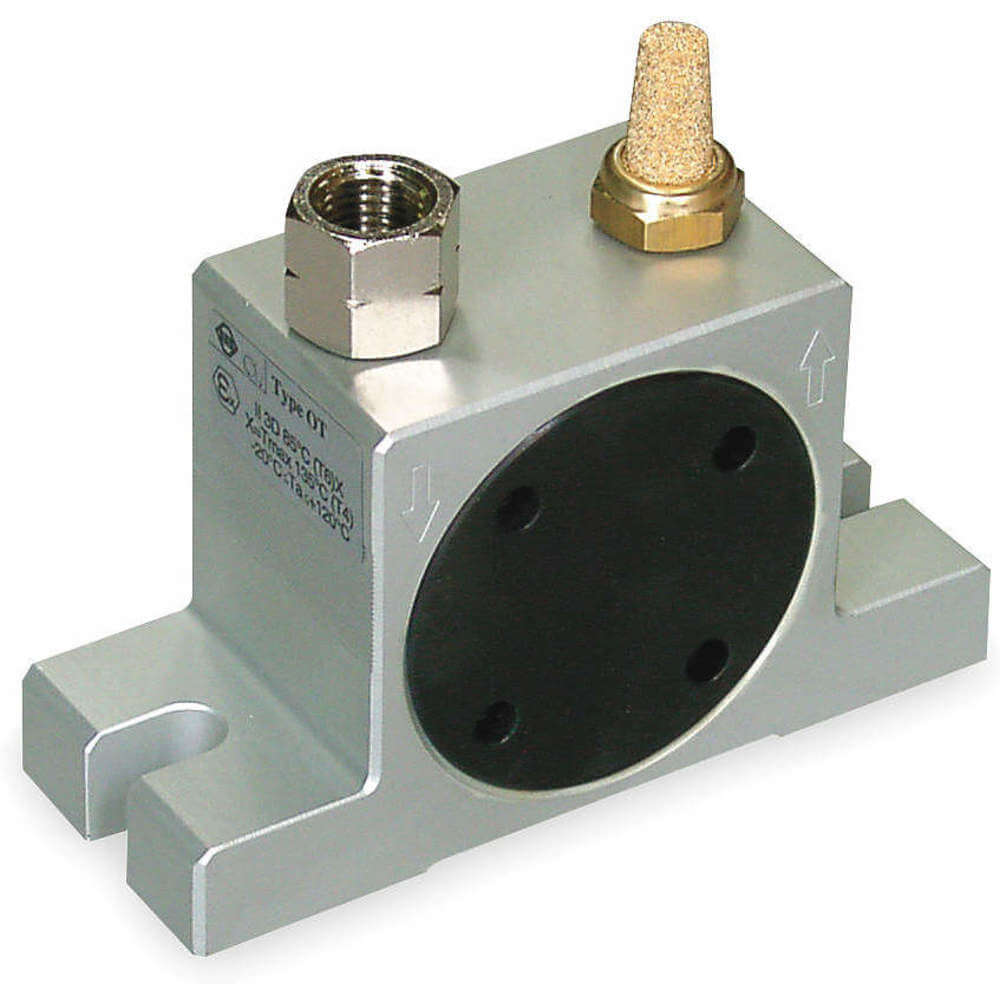

...Read morePneumatic Turbine Vibrators

Dayton pneumatic turbine vibrators are used in the biotech, plastic, chemical and automotive industries for providing high-frequency, low-amplitude & gentle vibration. They feature aluminium housing for corrosion resistance and allow all position mounting for easy installation. These vibrators can withstand temperatures up to 250 degrees F and are available in heights of 2.5, 3.125 & 4 inches.

Dayton pneumatic turbine vibrators are used in the biotech, plastic, chemical and automotive industries for providing high-frequency, low-amplitude & gentle vibration. They feature aluminium housing for corrosion resistance and allow all position mounting for easy installation. These vibrators can withstand temperatures up to 250 degrees F and are available in heights of 2.5, 3.125 & 4 inches.

| Style | Model | MPN | |

|---|---|---|---|

| A | 1520125 | RFQ | |

| A | 1520125K-JN | RFQ | |

| A | 1520125K-SN | RFQ | |

| A | 1520200 | RFQ | |

| A | 1520200K-JN | RFQ | |

| A | 1520200K-SN | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | 2520125 | RFQ | |

| A | 2520125K-JN | RFQ | |

| A | 2520125K-SN | RFQ | |

| A | 2520200 | RFQ | |

| A | 2520200K-JN | RFQ | |

| A | 2520200K-SN | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | 2500125K-JN | RFQ | |

| A | 2500150K-JN | RFQ | |

| A | 2500200K-JN | RFQ | |

| A | 2500300K-JN | RFQ | |

| A | 2500350K-JN | RFQ | |

| A | 2500400K-JN | RFQ | |

| A | 2500500K-JN | RFQ | |

| A | 2500700K-JN | RFQ | |

| A | 2500900K-JN | RFQ |

| Style | Model | MPN | |

|---|---|---|---|

| A | 1500125K-JN | RFQ | |

| A | 1500150K-JN | RFQ | |

| A | 1500200K-JN | RFQ | |

| A | 1500300K-JN | RFQ | |

| A | 1500350K-JN | RFQ | |

| A | 1500400K-JN | RFQ | |

| A | 1500500K-JN | RFQ | |

| A | 1500700K-JN | RFQ | |

| A | 1500900K-JN | RFQ |

VM Series Miniature Piston Vibrators

Turbomite CVT-P Series Quiet Turbine Vibrators, Acetal Plastic Body

Turbomite CVT-A Series Quiet Turbine Vibrators, Anodized Aluminium Body, SS Cap

SVRWS Series High Frequency Pneumatic Vibrators

| Style | Model | Vibrator Type | Force Rating | Speed @ 80 Psi | Overall Length | Overall Width | Overall Height | Duty | Mounting Plate | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | SVRWS-6500 | €2,123.88 | |||||||||

| B | SVRWS-5500 | €1,955.06 |

Working Mechanism

- Compressed air is supplied to the inlet of a pneumatic vibrator unit using a pipe or hose.

- The compressed air in turn powers the internal moving parts like the piston, turbine or ball bearing to convert the energy from the compressed air into mechanical energy.

- This mechanical energy is transferred to the material being vibrated through the vibrator's mounting plate.

- The vibrated materials move around, breaking any clogs or blockages and allowing free flow of the material.

- Ensure that the vibrators receive an adequate supply of air at the correct pressure to generate enough vibrations to move the material.

Frequently Asked Questions

How to know the size of the pneumatic vibrator needed for my application?

The size of a pneumatic vibrator depends on the specific application requirements, including the size & weight of the material being vibrated, the dimensions of the bin, hopper or chute where the vibrator will be used and the desired vibration amplitude & frequency.

Do pneumatic vibrators require any maintenance?

Pneumatic vibrators generally require relatively low maintenance. But they may need some care & cleaning for optimal performance. Users may also have to lubricate the moving parts, clean dust & debris from the vibrator and check for any leaks or worn parts that require replacement. Regular maintenance can increase the life of a vibrator and improve its performance over time.

How to install these pneumatic vibrators?

- Attach the vibrator to the mounting plate using the appropriate hardware.

- Connect the air supply to the inlet of the vibrator.

- Properly align the vibrator for optimal performance.

- Check for any leaks or other issues that may affect the performance of the vibrator.

- Refer to the installation instructions for specific guidance.

What are the advantages of pneumatic vibrators over electric vibrators?

- They do not require electrical power making them ideal for remote or hazardous areas.

- Pneumatic vibrators are generally more durable & reliable than electric vibrators.

- They are less expensive to operate and maintain.

- The pneumatic vibrators do not get affected by electrical interference & power fluctuations.

- They do not generate heat.

Popular Search Queries

Explore More

- UNITED SHIELD

- KEYSHAFT

- Flap Discs

- Anti-Slip Tapes

- Sequencers

- Intrusion Systems

- Specialty Hinges

- Reducers, Solid Input Shaft Hollow Bore Output Worm Gear - BOSTON GEAR

- Screwdriver Bit Sockets, 3/8 Inch Square Drive - CEMENTEX USA

- Square Files - NICHOLSON

- Bench Squeegee - VIKAN

- Natural Rubber Gloves - ANSELL

- 80-813 Activarmr Flame Resistant Gloves - ANSELL

- Refrigeration Compressors - EMBRACO

- Leather Gloves, Cowhide, Premium, Full Finger, Red/White - CONDOR

- Finger Guard, Grain Leather Cowhide - KAREWEAR