Jaw Coupling Spiders

Jaw coupling spiders are used to connect two shafts for torque transmission between them. They absorb shocks and vibrations and compensate for misalignment between the two shafts. These jaw

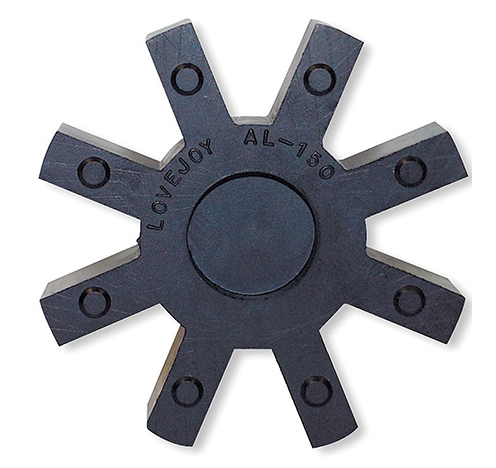

...Read moreSpider, SOX NBR, Solid, AL150 Size, 80A Shore Hardness, Jaw Coupling Type

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 68514418027 | AJ2XBT | €62.71 |

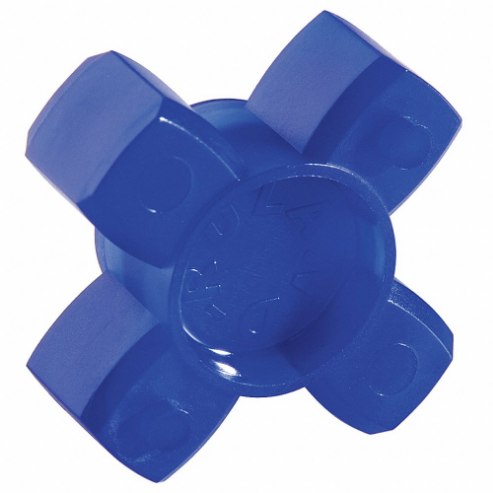

Urethane Spider Jc12/mjc19 Coupling Size

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| JD12/19-85B | AC9NNH | €31.71 |

Large Spider

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| LS/17640 | CD8ELA | €4.03 | RFQ |

Jaw Coupling Spiders

Jaw coupling spiders are used for torque transmission between two shafts and protecting components from damage by dampening vibrations & shocks. Raptor Supplies offers a wide range of reliable jaw coupling spiders from brands such as Boston Gear, Dayton, Lovejoy, Lisle and TB Wood's. Lovejoy L type spiders are designed to accommodate angular and parallel shaft misalignment. These spiders feature urethane, hytrel, bronze or SOX (NBR) rubber construction ensuring excellent abrasion resistance and protection against dirt, oil, sand, grease & moisture. They prevent metal to metal contact, ensuring in less internal wear and deliver torque up to 704 Nm. TB Wood’s urethane jaw coupling inserts are designed for adjusting a maximum of 0.015 inch parallel and 1 degree angular misalignments. These inserts provide 1.5 times higher torque than Buna N inserts, but with reduced vibration damping. They are capable of being operated at temperatures ranging between -30 and 160 degrees F. These jaw coupling spiders are available in heights ranging from 0.44 to 5 inches on Raptor Supplies.

Working Mechanism

- The jaw coupling consists of two hubs with curved jaws that interlock with a spider placed in between.

- When torque is applied to one of the hubs, it causes the jaws (on that hub) to grip the spider.

- This mechanism transfers the torque to the other hub through the jaws on the other side of the spider.

Frequently Asked Questions

How to select the right jaw coupling spider for my application?

The selection of a jaw coupling spider depends on the torque capacity, shaft size, operating temperature and chemical compatibility of the material with the fluids or gases being transferred.

How do I install a jaw coupling spider?

- Ensure that the shafts are properly aligned and clean.

- Place the spider between two coupling hubs and align jaws of hubs with the teeth of the spider.

- Tighten the screws or bolts on the hubs to secure the spider.

- Finally, check for proper alignment and ensure that the spider is not overstretched or damaged.

How do I maintain a jaw coupling spider?

- Regularly inspect it for signs of wear, damage or stretching.

- Clean the spider and coupling hubs to prevent the buildup of debris or contaminants.

Popular Search Queries

Explore More

- EASTERN METAL SIGNS AND SAFETY

- VISUAL WORKPLACE INC

- BARKSDALE

- KEYSHAFT

- HVAC Brushes

- Carbon Steel Pipe Fittings

- Condensate Pump Accessories

- Winch Cables

- Engravers

- Post - NEW AGE

- Deadbolt Locks - ABLOY

- Pockets - MCR SAFETY

- Grit Trax Wet Area Mattings - NOTRAX

- Double Containment Tees PVC Schedule 40 x PVC Schedule 40 Clear - SPEARS VALVES

- QRS Series Rotary Screw Air Compressors - CHICAGO PNEUMATIC

- 13018 Stak-N-Store Bins - AKRO-MILS

- ProLine Field Layout Systems - NEWSTRIPE

- Window Vests - DMS

- 477B Series Handheld Digital Manometers - DWYER INSTRUMENTS