Drum Pumps

Drum pumps are commonly used for transferring liquids from drums or containers. They are used in chemical processing, pharmaceuticals, food & beverage production and automotive

...Read moreDrum Pump Nozzle, Auto, Diesel Exhaust Fluid Compatible, 3/4 Inch Inlet Size, Bsp, Bsp

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| F0061700A | CT7UXZ | €369.85 |

Drum Pump Nozzle, Auto, Diesel Exhaust Fluid Compatible, Metered, 3/4 Inch Inlet Size, Bsp

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| F0061701A | CT7UYA | €668.51 |

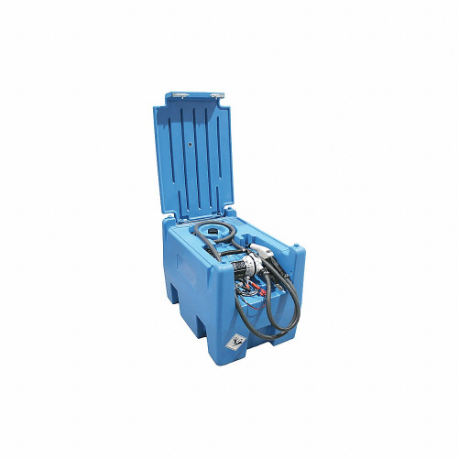

Electric Operated Drum Pump, 1/10 Hp Motor Hp, 275 Gal-330 Gal For Container Size, 12VDC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| F00204080 | CT7UYB | €536.67 |

Electric Operated Drum Pump, 1/10 Hp Motor Hp, 55 Gal For Container Size

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| F00102000 | CT7UYC | €2,957.35 |

Electric Operated Drum Pump, 2/3 Hp Motor Hp, 275 Gal-330 Gal For Container Size, 110VAC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| F00201A5J | CT7UYD | €1,196.69 |

Electric Operated Drum Pump, 2/3 Hp Motor Hp, 275 Gal-330 Gal For Container Size, 110VAC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| RKDEFPEDTL | CT7UYE | €2,828.96 |

Electric Operated Drum Pump, 1 1/10 Hp Motor Hp, 275 Gal For Container Size, 110VAC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| SP-ENC-V/SP-8850-47 | CU4HEH | €6,040.97 |

Electric Operated Drum Pump, 1 1/10 Hp Motor Hp, 275 Gal For Container Size, 220VAC

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| SP-ENC-2-V/SP-8850-47 | CU4HEJ | €6,084.83 |

Air Operated Drum Pump, 55 Gal For Container Size, 11 Gpm

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| E5PP6X659D-DRUM | CU7WQD | €2,484.65 |

Air Operated Drum Pump, 55 Gal For Container Size, 11 Gpm

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| E5PP5T559D-DRUM | CU7WQE | €2,997.57 |

Dual Port Tote Cap, Polyethylene

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| DEF5792 | CN9RQP | €55.78 |

Drum Pumps

Drum pumps are designed for transferring / removing fluids, oils and fuels without pivoting or tipping heavy drums in refining and food & beverage processing applications. Raptor Supplies offers a wide array of Action Pump, Basco, Dayton, Fill-Rate, Finish Thompson, GPI, National Spencer, Plews-Lubrimatic, Red Head, Rule, Sotera and Vestil drum pumps featuring a compact design for ensuring maximum job-site portability. Dayton electric drum pumps come with an integrated AC-powered electric motor for delivering flow rates up to 22 gpm, thermal protection facility for preventing overheating conditions and variable speed settings for adjusting to any required applications. Drum pumps from Fill-Rate feature aluminium / 304 stainless-steel / polypropylene construction for providing impact strength and protection against harsh industrial abuse. Choose from a wide range of these pumps available in 5.4, 5.9 & 6A current rating options.

Frequently Asked Questions

What factors should I consider while choosing a drum pump?

- Consider the fluid's viscosity for proper pump selection.

- Choose a pump suitable for your drum size.

- Verify materials can handle the fluid without corrosion.

- Determine the required flow rate for efficient transfer.

- Select based on manual / electric operation and type (e.g., rotary, piston).

- Assess if the pump is easy to move between drums.

- Look for grounding straps, explosion-proof motors or leak-proof seals for hazardous fluids.

How do I install drum pumps?

- Inspect the pump and drum for any damage or defects before installation.

- Position the drum pump near the drum that contains the fluid you want to transfer.

- Ensure the drum is securely stabilised and positioned on a level surface to prevent tipping.

- Remove the drum's bung or lid to access the interior.

- Insert the suction tube of the drum pump into the drum, ensuring it reaches the bottom.

- Secure the pump to the drum using any provided fasteners or clamps, ensuring a tight seal.

- Connect the discharge hose of the pump to the desired outlet or container for fluid transfer.

- Prime the pump by manually operating the pump handle or activating any priming mechanism.

- Turn on the pump and begin transferring fluid from the drum to the desired location.

- Monitor the fluid transfer process and adjust the pump's speed or flow rate as needed.

How do I clean and maintain these drum pumps?

- After each use, flush the drum pump with a compatible solvent or cleaning solution.

- Use a brush or cloth to remove any residue or debris from the pump's surfaces.

- Rinse the pump thoroughly with clean water to remove any remaining cleaning solution.

- Dry the pump completely with a clean, dry cloth to prevent rust or corrosion.

- Inspect the pump for any signs of wear, damage or leaks.

- Tighten any loose fittings or connections as needed.

- Apply a light coating of lubricant to moving parts to ensure smooth operation.

Explore More

- Switches

- Casters and Wheels

- Arc Welders and Plasma Cutter Consumables and Accessories

- Engines

- Prying Tools

- Auxiliary Contacts

- Specialty Casters

- Carriage Bolts

- Wall Mount Jibs

- Receptacle and GFCI Tester Accessories

- LOOS Strap Eye End Fitting

- DAYTON Capacitor Start Dual Shaft Power Tool Motors

- JABSCO Flexible Impeller Standard

- WEARWELL 574 Series, Modular Antifatigue Mat

- JAMCO Model CZ Adjustable Shelf Stock Truck

- DIXON DQC Ea-Series Seal Kits

- ALL GEAR Twisted Seine Twines

- SMC VALVES Gasket

- REGAL Cobalt End Mills, Double End, HSS, CC, 4 Flutes, Bright

- CHICAGO PNEUMATIC Cams