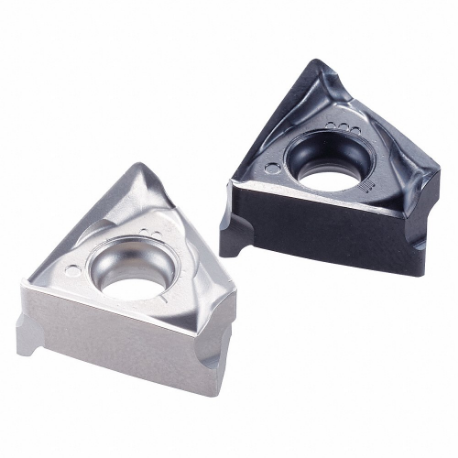

| Item | Milling Insert |

| Ansi Number | TNKU120608ER-GM |

| Cast Iron (k) Compatibility | Yes |

| Chip-breaker | Yes |

| Chip-breaker Code | GM |

| Clearance Angle | 0° |

| Coating | Chemical vapor deposition |

| Compatibility | Yes |

| Corner Radius | 0.8 mm |

| Countersink Hole Angle | 40° to 60° |

| Cutting Application | Finishing |

| Cutting Direction | Right Hand |

| Features | Composed Of A Tough High-Strength Carbide Material With A Chipping Resistant And Wear Resistant Coating |

| Finish | Titanium Carbonitride, Aluminum Oxide |

| For Toolholder | PSTW12R050M22-3, PSTW12R050M22-4, PSTW12R063M22-3, PSTW12R063M22-5, PSTW12R080M25.4-5, PSTW12R080M25.4-6, PSTW12R080M27-5, PSTW12R080M27-6, PSTW12R100M31.7-5, PSTW12R100M31.7-7, PSTW12R100M32-5, PSTW12R100M32-7, PSTW12R125M38.1-7, PSTW12R125M38.1-9, PSTW12R125M40-7, PSTW12R125M40-9 |

| For Use With | Indexable Ballnose End Mills |

| Hardened Compatibility | No |

| Hole Type | Countersink Hole |

| Included Angle | 60° |

| Inscribed Circle | 10.8 mm |

| Insert Application | Finishing |

| Insert Holding Type | Screw |

| Insert Size | 120608 |

| Material | Carbide |

| Mfr. Series | 78PSTW |

| Mounting Style | Screw |

| No. Of Edges | 6 |

| Non Ferrous (n) Compatibility | No |

| Number Of Cutting Edges | 6 |

| Primary Material Application | Steel |

| Primary Material Application Iso Code | P |

| Secondary Material Application | Cast Iron |

| Secondary Material Application Iso Code | K |

| Shape | Triangle |

| Stainless Compatibility | No |

| Style | TNKU |

| Super Alloy Compatibility | No |

| System Of Measurement | Metric |

| Thickness | 6.55 mm |

| Workpiece Compatibility | Steel |

| Ansi Code | TNKU120608ER-GM |

| Coating Process | CVD |

| Finish - Machining | TiCN+Al2O3 |

| Insert Style | TNKU |

| Iso Number | TNKU120608ER-GM |

| Lead Angle | 25° |

| Manufacturer Grade | XC3030 |

| Material - Machining | Carbide |

| Measurement System | Metric |

| Series | 78PSTW Series |