MORSE DRUM Poly Drum Roller Option for Stationary Drum Roller

Filter

| Style | Model | For Use With | Other | Capacity | Drum Material | Number Of Wheels | Price | |

|---|---|---|---|---|---|---|---|---|

| A | POLY-2-5154FI | 5154 Double-Drum Series | Field Installed | 55 gal. | Plastic | 8 | €883.32 | |

| A | POLY-2-5154 | 5154 Double-Drum Series | Factory Installation | 55 gal. | Plastic | - | €1,122.07 | |

| B | POLY-1-5154 | 5154 Single-Drum Series | Factory Installation | 55 gal. | Plastic | - | €696.06 | |

| A | POLY-1-5154FI | 5154 Single-Drum Series | Field Installed | 55 gal. | Plastic | - | €548.73 |

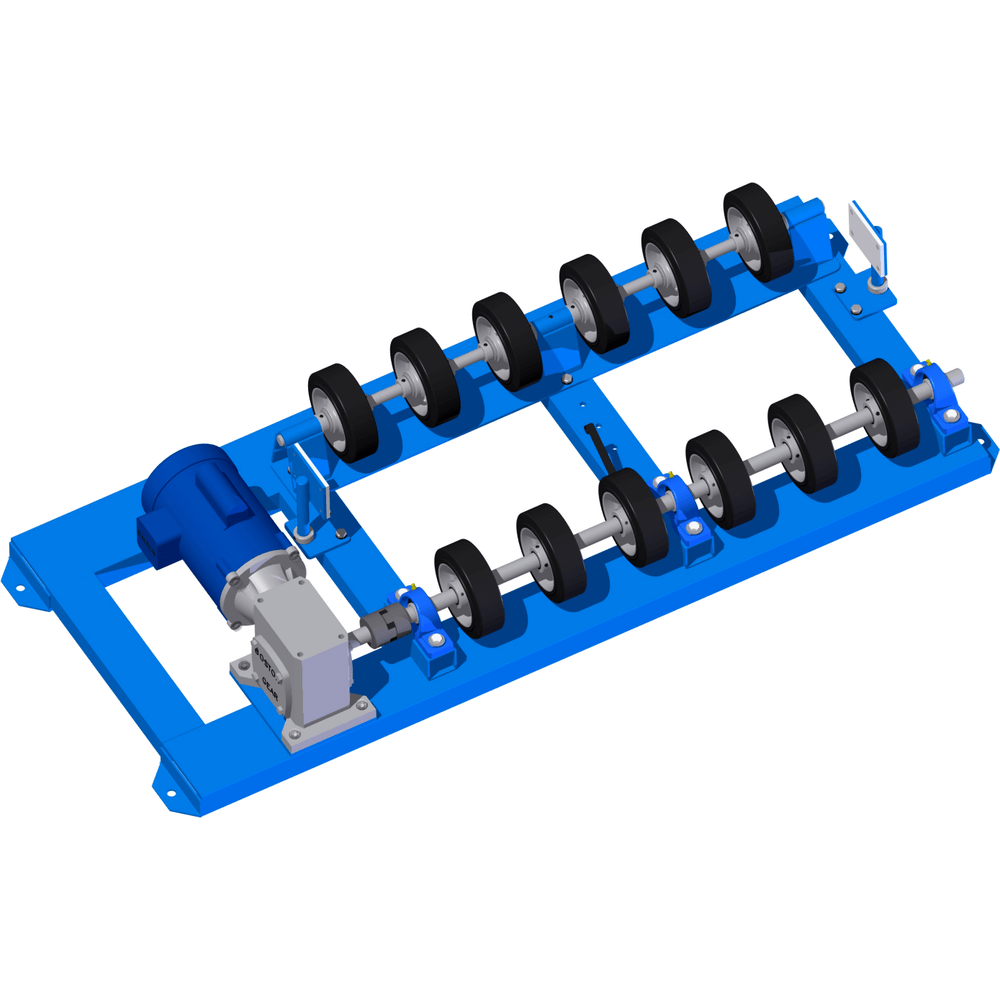

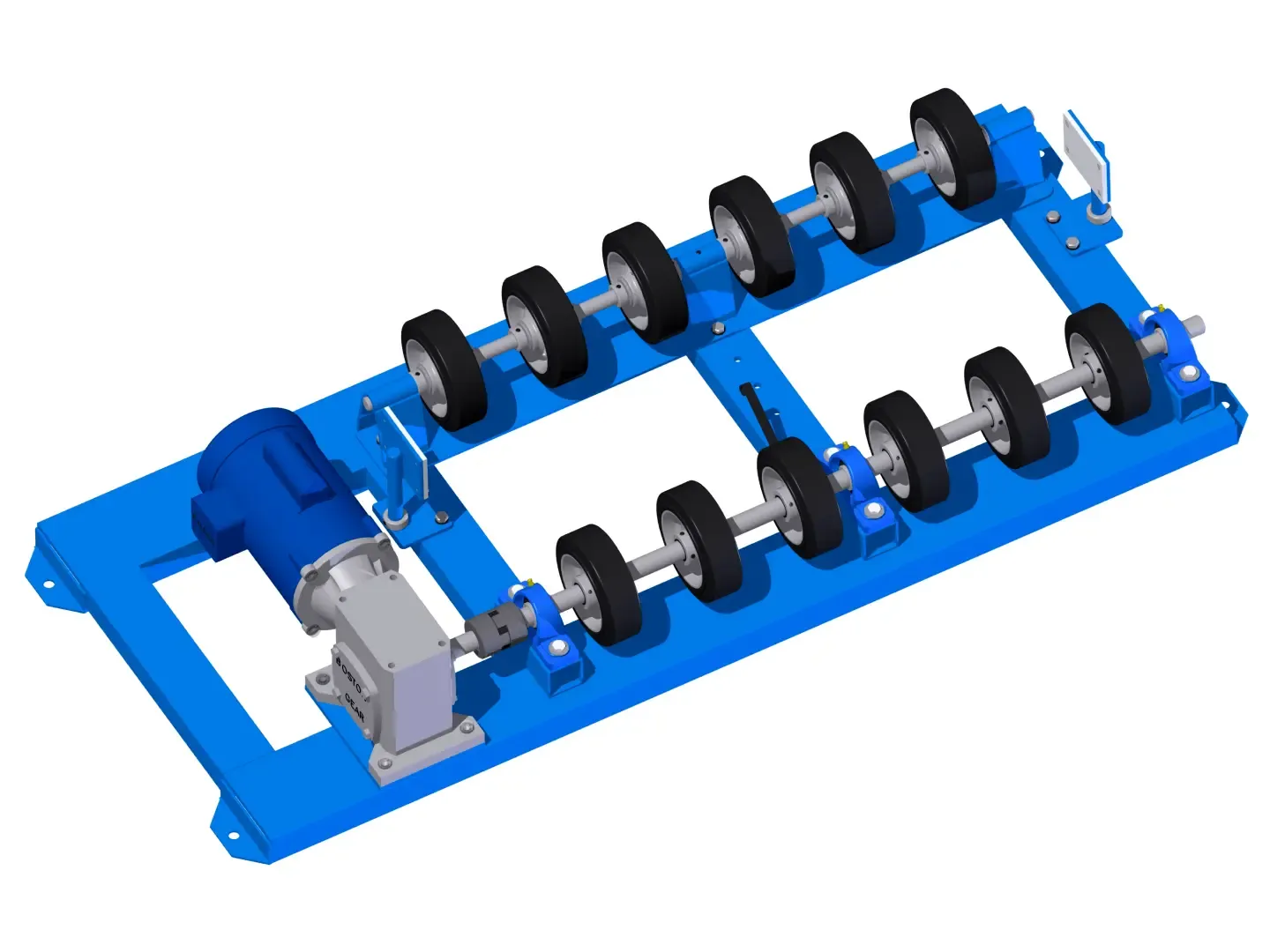

Poly Drum Roller Option for Stationary Drum Roller

Morse poly drum roller optional attachments are versatile options designed for stationary drum rollers. They facilitate the mixing and blending of contents within drums homogenously. These poly drum roller's optional attachments are ideal for applications in the chemical processing, pharmaceutical and manufacturing industries.

Working Mechanism

- Morse poly drum roller optional attachments operate with a fixed RPM, utilising a motorised / pneumatic rotation system to efficiently mix liquids within the drum. They employ four drive wheels and four idler wheels to provide stable support and ensure a consistent and controlled speed for effective mixing.

Features

- Morse poly drum roller optional attachments feature a fixed RPM of 20, providing optimal mixing for liquids within a 22.5-inch drum.

- These poly drum roller optional attachments can roll two drums simultaneously ranging from 6 to 28 inches in diameter and up to 40 inches in height.

- They offer a liquid load capacity of 1000 lb per drum and a dry load capacity of 300 lb at 20 RPM.

- These poly drum roller options offer customisable control packages for 115V / 1PH, 208V / 1PH or 230V / 1PH operation, allowing users to tailor the equipment to their specific power requirements.

- They are equipped with air-powered Morse 2-5154-A poly drum roller that includes a control package, requiring plant air at 40 PSI and a flow rate of 40 SCFM.

Frequently Asked Questions

How does the motorised rotation system function in these poly drum roller optional attachments?

The motorised rotation system facilitates the controlled movement of the drum, promoting efficient blending of substances.

Why is the dry load rotation of these drum rollers less than the liquid load capacity?

It is because shifting dry load exerts greater stress on the drum roller than the fluid motion of a liquid load.

Is there a safety feature included in the poly drum roller optional attachment and what does it entail?

Yes, the equipment offers an OSHA-required gated enclosure with a door interlock, enhancing operator protection by preventing access to moving parts during operation.

We are here to help!

Looking for a part not listed here?

Explore More

- KEYSHAFT

- LABCONCO

- PRO SCIENTIFIC INC.

- YELLOW JACKET

- OMNI INTERNATIONAL

- PEX Tubing

- LED Wall Packs

- Gasoline Engines

- Confined Space Hoist Mounts

- Oscillating Tool Accessories

- 08-354 Alphatec Neoprene Chemical Resistant Gloves - ANSELL

- Mustang Leather Welding Work Gloves - MCR SAFETY

- Class 00 Electrical Insulating Rubber Gloves, 11 Inch, Red - SALISBURY

- Dovetail Cutters, Carbide Tipped - KEO

- ANVIL 2154 Series Socket Weld Couplings, Forged Steel

- Plastic Photoelectric Area Sensor, 20mm Beam Spacing - AUTONICS

- E2E2 Cylindrical Proximity Sensor - OMRON

- Skystep Red Mattings - NOTRAX

- Sleeve Straps - CEMENTEX USA

- Crimping Rolls - ROPER WHITNEY