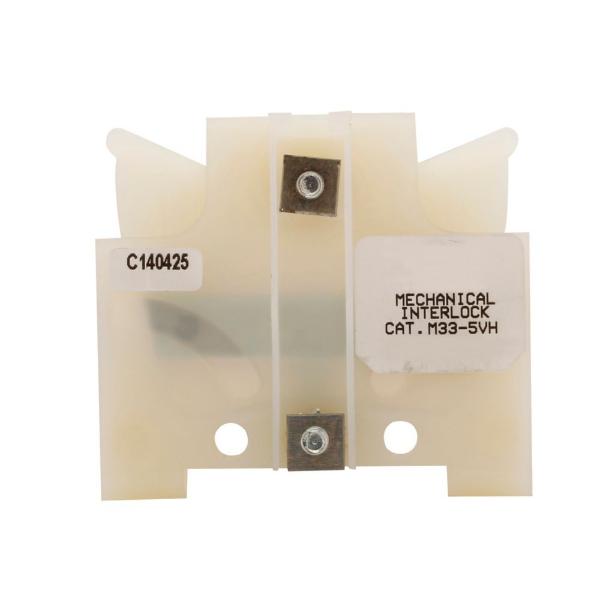

EATON A200 Series NEMA Motor Control Interlocks

Eaton A200 Series motor control interlocks are ideal for mechanically interlocking a motor starter to the load it controls. They ensure proper positioning of the motor starter to the load before the motor is started / stopped and prevent accidents or equipment damage. These mechanical interlocks are available in various sizes & configurations to suit different applications. They feature a compact design and are easy to install & maintain....Read more

| Style | Model | Depth | Height | Used With | Lens Color | Mounting Method | Options | Price | |

|---|---|---|---|---|---|---|---|---|---|

| A | M-33-3B | 2 3/5" | 3 3/5" | Starters | - | Horizontal | - | €815.70 | |

| B | M33-5VH | 2.7" | 3 4/5" | V210, V211 Size 5 Vacuum | - | - | Horizontal Starter Mounting | €646.65 | |

| C | M-33-2B | 2.7" | 3 2/5" | Starters | - | - | - | €488.23 | |

| D | M34-2A | 3 1/2" | 2 1/2" | Starters | - | - | - | €486.03 | |

| C | M-33-1B | 3 4/5" | 2 3/5" | Starters | - | - | - | €486.03 | |

| A | M-34-1A | 4 4/5" | 2 1/2" | Starters | - | - | - | - | RFQ

|

| D | M-35-2A | 4 4/5" | 2 1/2" | Starters | - | - | - | €486.03 | |

| E | 2050A11G75 | 6" | 2 1/2" | - | White | - | - | €3,367.49 | |

| D | M-34-3A | 8.3" | 5.1" | Type A Three Pole, Four Pole | - | - | - | €800.02 | |

| E | 2050A11G25 | 11 4/5" | 2" | - | Red | - | - | €3,367.49 |

Working Mechanism

- The mechanical interlocks have a stationary housing with a movable latch connected to the control circuit of the motor starter.

- After the motor starter is switched off, the latch remains in the locked position to prevent the load from opening or closing.

- After the motor starter is switched on, the latch gets released to allow the load to open or close based on the motor rotation direction.

- If the load is opened during the operation of the motor, the latch gets locked to stop the motor & prevent further damage to the equipment.

- When the motor starter is switched off, the latch locks the load again to prevent the load from opening or closing.

Standards and Approvals

- UL

- CSA

- NEMA

Frequently Asked Questions

How are these motor control interlocks installed?

Eaton A200 Series motor control interlocks can be easily installed by attaching them to both the motor starter & the load to be controlled. The specific installation process may vary based on the type of interlock used & the specific application requirements.

Do these Eaton A200 Series motor control interlocks require maintenance?

These mechanical interlocks require very low maintenance. However, they should be occasionally cleaned & inspected to ensure their functionality.

How do these motor control interlocks increase efficiency?

Eaton A200 Series motor control interlocks improve efficiency, reduce downtime & increase productivity by ensuring that the motor starter & the load are in the proper position before the motor is started or stopped.

We are here to help!

Looking for a part not listed here?

Explore More

- HIRETECH

- KEYSHAFT

- SCOTCH

- WARING COMMERCIAL

- VITEK

- Web Sling Wear Pads

- Calibration Kits and Stations

- Impact Socket Bit Drivers

- Hydraulic Quick Couplers

- ADA Pads

- 316 Stainless Steel Inline Ball Valve, Socket x Socket - SHARPE VALVES

- 3 Inch Chart Recorders - DICKSON

- Impact Socket, 6 Point, 3/8 Inch Drive, Metric - PROTO

- CU420 Gas Springs - ASSOCIATED SPRING RAYMOND

- Small Keyseat Cutters, Shank Type, Solid Carbide - KEO

- Scissor Lift Table Accordion Bellows - BISHAMON INDUSTRIES

- Bollard Kit, Plastic - ARLINGTON INDUSTRIES

- Angle Hose Valves - DIXON

- NoGo Standard Thread Plug Gages, 2 1/8-8 Un - VERMONT GAGE

- Pipettes - SIBATA