Spline Shafts And Couplings

Spline shafts and couplings are used in power transmission systems to transfer torque and rotation from one component to another. Spline shafts have a long, cylindrical rod-type design with

...Read more| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Dimension D | Dimension Hd | Min. Bore | Pin Location (dimension Sl) | Wind-up Angle At Max. Torque | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514413923 | €342.29 | |||||||||

| A | 68514413952 | €1,666.03 |

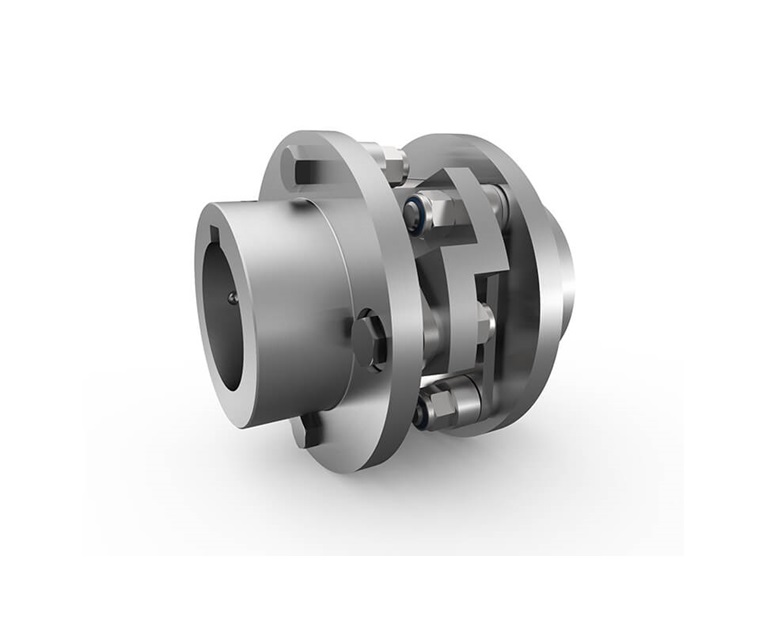

HSH Form Flex Couplings

TB Wood's HSH Form-Flex couplings are designed to transmit torque while compensating for angular, parallel and axial misalignment between two connected shafts. They minimise misalignment forces on the connected equipment and are widely used in cooling fan drive applications. These couplings are available with steel and composite spacer tubing that reduces total cost by eliminating the need for bearings and support structures. The brand's HSH Series Form-Flex couplings range from 1000 rpm to 3800 rpm. A wide range of these couplings (with bore length up to 11 inches) is available on Raptor Supplies.

TB Wood's HSH Form-Flex couplings are designed to transmit torque while compensating for angular, parallel and axial misalignment between two connected shafts. They minimise misalignment forces on the connected equipment and are widely used in cooling fan drive applications. These couplings are available with steel and composite spacer tubing that reduces total cost by eliminating the need for bearings and support structures. The brand's HSH Series Form-Flex couplings range from 1000 rpm to 3800 rpm. A wide range of these couplings (with bore length up to 11 inches) is available on Raptor Supplies.

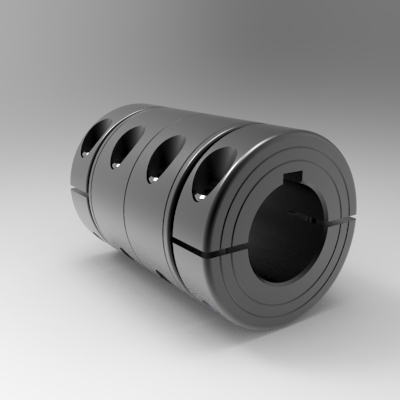

GCH Form Flex Couplings

TB Wood's GCH Form-Flex couplings are designed to connect two shafts for efficient power transmission applications in screw compressors, cooling towers or printing presses. These couplings come in a robust disc pack design for greater torque loads and lower weight per HP for a better inherent balance, as compared to rigid couplings. The high torsional stiffness feature of these couplings maintains the structural integrity of the system while counterbalancing angular or axial misalignments. They are integrated with a fail-safe mechanism that gets activated, when the element is damaged, by simply transmitting rotary motion via washers.

TB Wood's GCH Form-Flex couplings are designed to connect two shafts for efficient power transmission applications in screw compressors, cooling towers or printing presses. These couplings come in a robust disc pack design for greater torque loads and lower weight per HP for a better inherent balance, as compared to rigid couplings. The high torsional stiffness feature of these couplings maintains the structural integrity of the system while counterbalancing angular or axial misalignments. They are integrated with a fail-safe mechanism that gets activated, when the element is damaged, by simply transmitting rotary motion via washers.

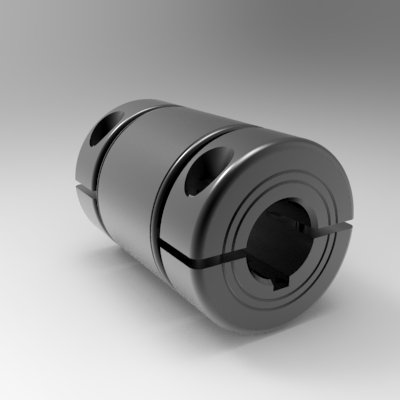

AA Form Flex Couplings

TB Wood's Form-Flex couplings connect two shafts and transmit torque / power effectively from one shaft to the other. They compensate for angular, parallel and axial misalignment between two connected shafts at a closer distance. These AA couplings feature a flexible disc to minimise misalignment forces and allow easy interchangeability, thereby reducing downtime & maintenance time. Choose from a wide range of these Form-Flex couplings, available in torque ratings ranging from 2363 to 17010 lb-inch on Raptor Supplies.

TB Wood's Form-Flex couplings connect two shafts and transmit torque / power effectively from one shaft to the other. They compensate for angular, parallel and axial misalignment between two connected shafts at a closer distance. These AA couplings feature a flexible disc to minimise misalignment forces and allow easy interchangeability, thereby reducing downtime & maintenance time. Choose from a wide range of these Form-Flex couplings, available in torque ratings ranging from 2363 to 17010 lb-inch on Raptor Supplies.

GCF Form Flex Couplings

TB Wood's GCF Form-Flex couplings are designed to transmit torque while compensating for angular, parallel and axial misalignments between two connected shafts. These couplings are integrated with a flexible disc to minimise the misalignment errors and feature a high torsional stiffness for maintaining the structural integrity of the system.

TB Wood's GCF Form-Flex couplings are designed to transmit torque while compensating for angular, parallel and axial misalignments between two connected shafts. These couplings are integrated with a flexible disc to minimise the misalignment errors and feature a high torsional stiffness for maintaining the structural integrity of the system.

| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Free End Float | Max. Rpm | Dimension G | Dimension B | Dimension D | Adapter Bcd | |

|---|---|---|---|---|---|---|---|---|---|---|

| A | GCF340-35-12HD | RFQ | ||||||||

| A | GCF340-31-14SAE | RFQ | ||||||||

| A | GCF340-35-20SAE | RFQ | ||||||||

| A | GCF340-35-12SAE | RFQ | ||||||||

| A | GCF340-31-20SAE | RFQ | ||||||||

| A | GCF340-31-22SAE | RFQ | ||||||||

| A | GCF340-31-12HD | RFQ | ||||||||

| A | GCF340-35-20HD | RFQ | ||||||||

| A | GCF340-35-22HD | RFQ | ||||||||

| A | GCF340-31-12SAE | RFQ | ||||||||

| A | GCF340-31-18SAE | RFQ | ||||||||

| A | GCF340-31-20HD | RFQ | ||||||||

| A | GCF340-35-18HD | RFQ | ||||||||

| A | GCF340-35-18SAE | RFQ | ||||||||

| A | GCF340-35-22SAE | RFQ | ||||||||

| A | GCF340-35-14SAE | RFQ | ||||||||

| A | GCF340-35-14HD | RFQ | ||||||||

| A | GCF412-42-20HD | RFQ | ||||||||

| A | GCF412-42-28SAE | RFQ | ||||||||

| A | GCF412-50-26SAE | RFQ | ||||||||

| A | GCF412-50-22SAE | RFQ | ||||||||

| A | GCF412-45-26HD | RFQ | ||||||||

| A | GCF412-45-28HD | RFQ | ||||||||

| A | GCF412-50-28HD | RFQ | ||||||||

| A | GCF412-42-20SAE | RFQ |

| Style | Model | Bore Size | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Dimension D | Material | Type | Keyway Size | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514413872 | €715.63 | |||||||||

| A | 68514413870 | €698.43 |

| Style | Model | MPN | |

|---|---|---|---|

| A | 1302264055 | RFQ | |

| A | 1302264056 | RFQ | |

| A | 1302264066 | RFQ | |

| A | 1302264080 | RFQ | |

| A | 1302264102 | RFQ | |

| A | 1302264104 | RFQ |

| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Dimension D | Bore Size | Dimension Hd | Overall Length | Pin Location (dimension Sl) | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514413740 | €219.92 | RFQ | ||||||||

| A | 68514413695 | €173.57 | RFQ |

| Style | Model | Max. Bore | Max. Rpm | Outside Dia. | Dimension L | Dimension Hd | Overall Length | Length Through Bore | Dimension Bc | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514426081 | €1,319.53 | |||||||||

| A | 68514426085 | €4,739.99 |

| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Dimension Hd | Overall Length | Min. Bore | Length Through Bore | Pin Location (dimension Sl) | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514441950 | €420.46 | |||||||||

| A | 68514413359 | €715.63 | |||||||||

| A | 68514444809 | €498.39 | |||||||||

| A | 68514413103 | €498.39 | |||||||||

| A | 68514450849 | €579.76 |

| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Dimension Hd | Overall Length | Min. Bore | Length Through Bore | Pin Location (dimension Sl) | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514426095 | €326.12 | |||||||||

| A | 68514413040 | €410.24 | |||||||||

| A | 68514451046 | €420.46 | |||||||||

| A | 68514444217 | €528.90 | |||||||||

| A | 68514413139 | €528.90 | |||||||||

| A | 68514413015 | €336.31 | |||||||||

| A | 68514451037 | €715.63 | |||||||||

| A | 68514413084 | €498.39 | |||||||||

| A | 68514413209 | €579.76 |

| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Keyway Size | Dimension Hd | Overall Length | Min. Bore | Length Through Bore | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514444219 | €1,989.90 | |||||||||

| A | 68514413541 | €1,217.70 | |||||||||

| A | 68514448325 | €1,217.70 | |||||||||

| A | 68514413461 | €1,078.15 | |||||||||

| A | 68514426105 | €1,091.83 | |||||||||

| A | 68514413351 | €698.43 | |||||||||

| A | 68514426099 | €698.43 | |||||||||

| A | 68514444108 | €715.63 | |||||||||

| A | 68514444307 | €579.76 | |||||||||

| A | 68514413255 | €579.76 | |||||||||

| A | 68514413409 | €759.46 |

| Style | Model | Max. Bore | Hp Rating @ 100 Rpm | Max. Rpm | Keyway Size | Dimension Hd | Overall Length | Min. Bore | Length Through Bore | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68514413570 | €1,206.98 | |||||||||

| A | 68514445193 | €1,217.70 | |||||||||

| A | 68514444584 | €1,217.70 | |||||||||

| A | 68514444113 | €1,217.70 | |||||||||

| A | 68514445717 | €1,699.97 | |||||||||

| A | 68514446309 | €1,091.83 | |||||||||

| A | 68514413493 | €1,078.15 | |||||||||

| A | 68514426098 | €528.90 | |||||||||

| A | 68514413384 | €715.63 | |||||||||

| A | 68514426100 | €652.27 | |||||||||

| A | 68514445477 | €546.93 | |||||||||

| A | 68514413300 | €579.76 | |||||||||

| A | 68514447442 | €579.76 | |||||||||

| A | 68514445248 | €777.86 | |||||||||

| A | 68514426104 | €777.86 | |||||||||

| A | 68514426103 | €777.86 | |||||||||

| A | 68514413426 | €511.50 | RFQ |

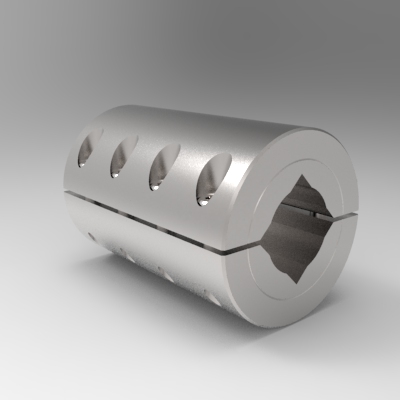

Signature Series, One Piece Split Precision Sleeve Couplings

| Style | Model | Outside Dia. | Bore Size | Total Length | Keyway Size | Screw Size | Material | Type | Screw Material | Price | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 5L010010KPSC | €137.56 | RFQ | ||||||||

| B | 5L010010FKPSC | €176.09 | RFQ | ||||||||

| A | 5L008008KPSC | €113.54 | RFQ | ||||||||

| B | 5L008008FKPSC | €150.86 | RFQ | ||||||||

| A | 5L012012KPSC | €129.76 | RFQ | ||||||||

| B | 5L012012FKPSC | €151.43 | RFQ | ||||||||

| A | 5L108108KPSC | €203.02 | RFQ | ||||||||

| B | 5L108108FKPSC | €231.16 | RFQ | ||||||||

| A | 5L104104KPSC | - | RFQ | ||||||||

| B | 5L104104FKPSC | - | RFQ | ||||||||

| A | 5L100100KPSC | €139.00 | RFQ | ||||||||

| B | 5L100100FKPSC | €180.25 | RFQ |

| Style | Model | Outside Dia. | Total Length | Bore Size | Bore Size A | Bore Size B | Material | Grade | Screw Material | |

|---|---|---|---|---|---|---|---|---|---|---|

| A | UPS-A012012N | RFQ | ||||||||

| A | UPS-A012008N | RFQ | ||||||||

| A | UPS-A008008N | RFQ | ||||||||

| A | UPS-A100008N | RFQ | ||||||||

| A | UPS-A100012N | RFQ | ||||||||

| A | UPS-A100100N | RFQ |

| Style | Model | Outside Dia. | Total Length | Bore Size | Bore Size A | Bore Size B | Material | Grade | Screw Material | |

|---|---|---|---|---|---|---|---|---|---|---|

| A | UPS-A012012P | RFQ | ||||||||

| A | UPS-A012008P | RFQ | ||||||||

| A | UPS-A008008P | RFQ | ||||||||

| A | UPS-A100100P | RFQ | ||||||||

| A | UPS-A100012P | RFQ | ||||||||

| A | UPS-A100008P | RFQ |

Spline Shafts And Couplings

Hub City spline shafts are specially designed for transmitting high amount of torque force and rotation. These plain and involute splined shafts feature 1215 cold-rolled steel to deliver fair vibration damping and excellent chemical resistance. We also offer Hub City couplings in 1144 stress-proofed steel to connect and transmit torque between two rotating shafts. These couplers feature Kwik-D-Tach connection for safe and secure attachments.

Working Mechanism

- The shafts of the machinery are positioned in such as way that their ends are facing each other.

- The spline shaft is inserted securely into the grooves of the coupling.

- The coupling is then fastened onto the end of the other shaft by using bolts or clamps.

- When torque is applied to one of the shafts, it is transmitted through the spline shaft and coupling to the other shaft, causing both shafts to rotate at the same speed.

Frequently Asked Questions

What is overall length tolerance?

OAL (overall length tolerance) refers to the allowable deviation from the nominal or desired length of the coupling. It helps to position and align the coupling on the shafts it is connecting.

What is the purpose of keyways in Lovejoy couplings?

Keyways are grooves or slots that are machined into the bore of the coupling hub and include a matching key that is installed in the keyway to connect the hub to the shaft. These keyways help transmit torque, ease installation and provide accurate alignment between the shaft and the coupling.

How to maintain a spline coupling?

- Regular visual inspections are needed to identify any signs of wear or damage of the spline coupling, such as cracks and corrosion.

- Ensure the coupling is properly aligned to maintain smooth operation and prevent premature wear.

- Regularly lubricate the coupling to prevent wear and reduce friction.

- Ensure that spline couplings are not subjected to overload conditions, as this can cause permanent deformation and reduce the strength of the spline teeth.

How do I select the right type of shaft coupling for my application?

The choice of coupling depends on shaft misalignment, torque requirements, speed and environmental conditions.

What is the difference between rigid couplings and flexible couplings?

Rigid couplings do not allow any angular or parallel misalignment between shafts. They provide a solid, backlash-free connection. In contrast, flexible couplings accommodate some degree of misalignment and are often used to dampen vibrations and shock loads in machinery.

How do I calculate the torque capacity of a spline shaft?

- To calculate the torque capacity of a spline shaft, you can use the formula:

- Torque (T) = Shaft Diameter (D) x Material Strength (S) x Safety Factor (SF)

What is the difference between external spline and internal spline configurations?

External spline refers to the presence of the splines on the outside surface of a shaft, while internal spline refers to the splines inside a cylindrical bore.

How does rigid, flexible and fluid connection coupling differ from each other?

Rigid couplings provide a solid connection with no flexibility, flexible couplings offer misalignment compensation, and fluid couplings use hydraulic principles for torque transmission and speed control.

Popular Search Queries

Explore More

- MARTIN SPROCKET

- ATTABOX

- KEYSHAFT

- Dock Ladders

- Roof Hatch Railing Systems

- Crane Scales and Dynamometers

- Mobile Bin Cart Accessories

- Class G Fuses

- Taper Bushed Type Timing Pulleys, L Belt Type - MARTIN SPROCKET

- Air Powered Scarifier - AURAND

- Wrist Wrap - CONDOR

- Type 12 Modular Free Stand Disconnect Barriers - HOFFMAN

- Luminator Reflective Rain Gears - MCR SAFETY

- Class 0 Electrical Gloves, 11 Inch, Yellow - ANSELL

- PVC Female Adapters - HARVEL CLEAR

- Workforce All Purpose Use Gloves - IRONCLAD

- High Visibility Cowhide Leather Orange Palm Gloves - CONDOR