Hydraulic Presses

Hydraulic presses are used in a wide range of industrial and manufacturing applications, such as forging, stamping, deep drawing and pressing. They use a fluid (oil) to generate a

...Read moreDouble Acting, Movable Cylinder, Movable Table Hydraulic Press

Hydraulic Presses

Indexable Profiling End Mill

Hydraulic Press

Hydraulic Presses

Hydraulic Presses

Hydraulic Shop Press

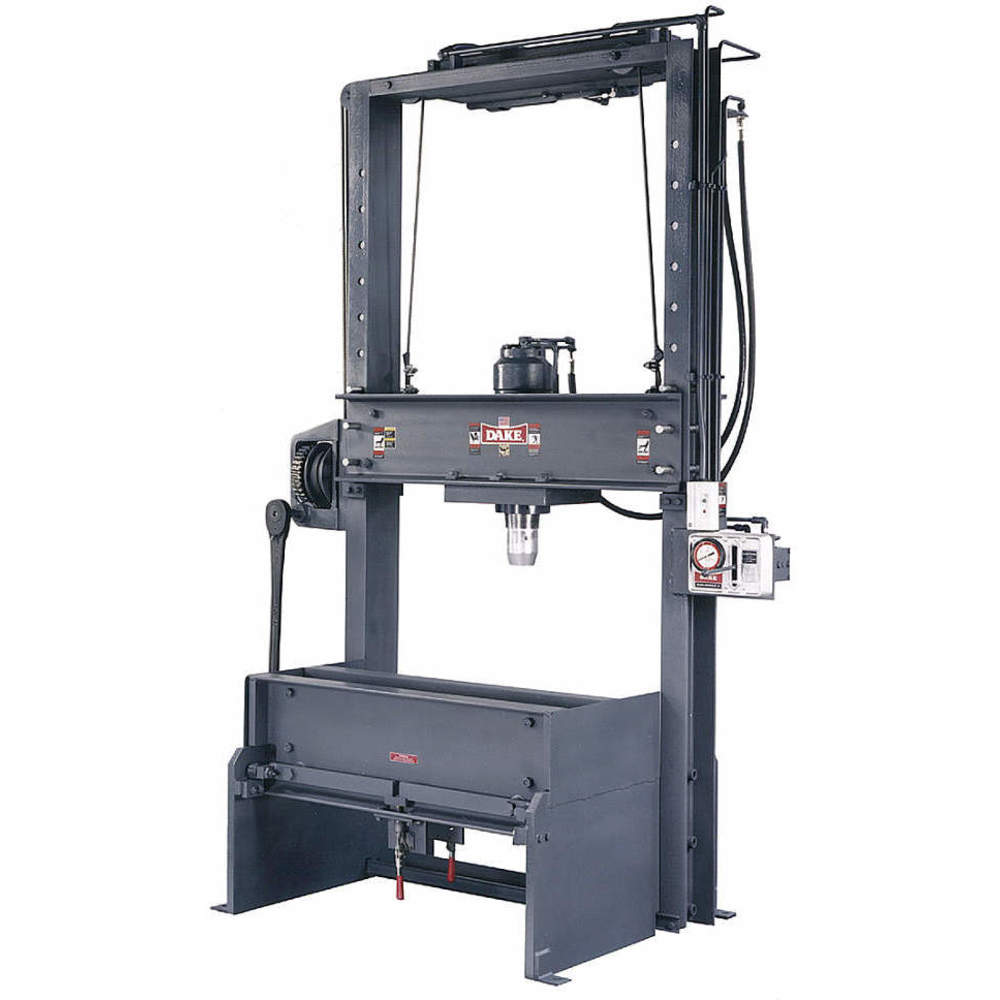

Double Acting, Fixed Cylinder, H-Frame Hydraulic Press

Hydraulic Economy Shop Press 12 Ton

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 1MZJ5 | AF6PVX | €778.82 |

Hydraulic Press, Floor Type, Manual Operation, H-Frame, 20 Ton Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 972220 | CJ6UEM | €1,616.16 |

Mountable Guard For Shop Press Mdl Sp-75

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| SP75S Guard | AA3KUJ | €5,148.44 |

Hydraulic Press, Hand Operated, 150 Ton Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 907005 | CJ6UCK | - | RFQ |

Hydraulic Press, Rolling Bed Type, Air Operated, Double Pump, 50 Ton Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 942304 | CJ6UDG | - | RFQ |

Hydraulic Press, Air Operated, Double Air Pumps, 150 Ton Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 906850 | CJ6UCH | - | RFQ |

Tire Press, Air Powered, 150 Ton Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 933587 | CJ6UDD | - | RFQ |

Hydraulic Press, Rolling Bed Type, Air Operated, Double Pump, 75 Ton Capacity

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| 942308 | CJ6UDH | - | RFQ |

Hydraulic Presses

We offer a wide range of hydraulic / arbor / C-clamp presses designed for applications in metal fabrication, cosmetic, pharmaceutical and glass manufacturing industries. For transforming metallic objects into sheets or thinning glass, these hydraulic press machines use a hydraulic cylinder to create a compressive force on the ram / piston which then transfers it to the fluid. Featuring a welded / bolted construction for maximum strength and durability, these hydraulic presses are offered in different frame capacities. Raptor Supplies offers a wide array of various hydraulic press manufacturers like Enerpac, Dake Corporation, Gray, Baileigh Industrial and OTC. For different applications, fixed / portable hydraulic press machines are available in movable, fixed, single-acting and double-acting cylinder options.

Frequently Asked Questions

What is the difference between single-acting and double-acting hydraulic presses?

- Single-acting presses have a single connection to a source of pressurised fluid and the other end is connected to a reservoir or return line.

- Double-acting presses, on the other hand, have two connections to a source of pressurised fluid, wherein one connection helps the cylinder to extend and the other let it retract during the operation.

What is the use of an H-frame hydraulic press?

The H-frame consists of two pillars that support the cylinder and the upper and lower platens. This design allows them to create better stability for tasks like stamping, punching, bending, cutting, forging, deep drawing and straightening metals or plastics. In addition, H-frame presses offer high precision, easy maintenance and the ability to withstand large loads.

Where are movable and fixed cylinders used?

- A movable cylinder moves about the press's frame where it needs to exert force on the workpiece. For example, in a stamping press, the cylinder moves downwards to apply force to the stamping die.

- Fixed cylinders are used in presses, where the cylinder is fixed on the punching plate while the workpiece is placed on a bed. In operation, the gliding screw provides an upward force while the cylinder provides a downward force to the upper body, causing the punching machine to move downwards with a greater impact and cut / shape the workpiece.

Explore More

- Labware

- Task Lights

- Plugs and Receptacles

- Concrete Mixing and Preparation

- Air Distribution Venting and Duct Accessories

- Supplied Air Respirators

- Wireless Monitoring Systems

- Absorbent Pillows

- Spanner and Hydrant Wrenches

- Forklift Lifting Beams and Hooks

- ENPAC Containment Pool

- NOVAFLEX Bulk Beverage Hoses

- APPROVED VENDOR Triangle Sanding

- VULCAN HART Back Panel

- EDWARDS SIGNALING 125 Class Incandescent Flashing Beacons

- PASS AND SEYMOUR Louver Wall Plates

- BLACK & DECKER Kerf Plates

- OSG High Performance Roughing/Finishing Carbide Ball End Mills

- TAPCO Folding Barricades

- YORK Gasket Kits