Hydraulic Flow Dividers

Hydraulic flow dividers are designed to distribute the single pump flow equally or in pre-defined ratios between 2 or more actuators. Raptor Supplies offers a wide range of hydraulic flow

...Read more| Style | Model | Flow Rate | Max. Outlet Pressure | Height | Gear Material | Function | Operating Pressure | Price | |

|---|---|---|---|---|---|---|---|---|---|

| A | AFT100-250/250-B-650 | €276.14 | |||||||

| A | AFT100-510/510-B-650 | €284.16 |

Hydraulic Flow Divider, 3/4 Inch NPT, 20 gpm to 35 gpm, 1, 1, Flow Divider, 3/4 Inch NPT

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| PDC-75-50 | AK7PYD | €264.38 |

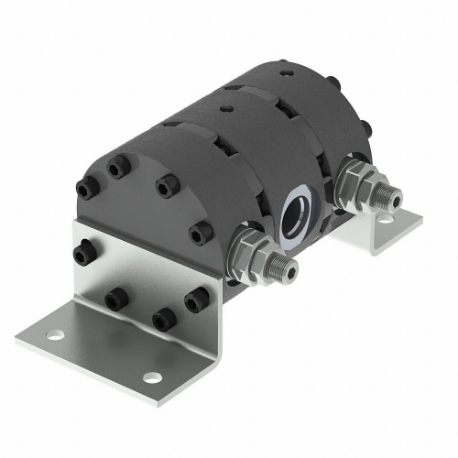

Hydraulic Flow Divider Rotary Gear

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| FM-4R4.2S | AH4UVY | €988.45 |

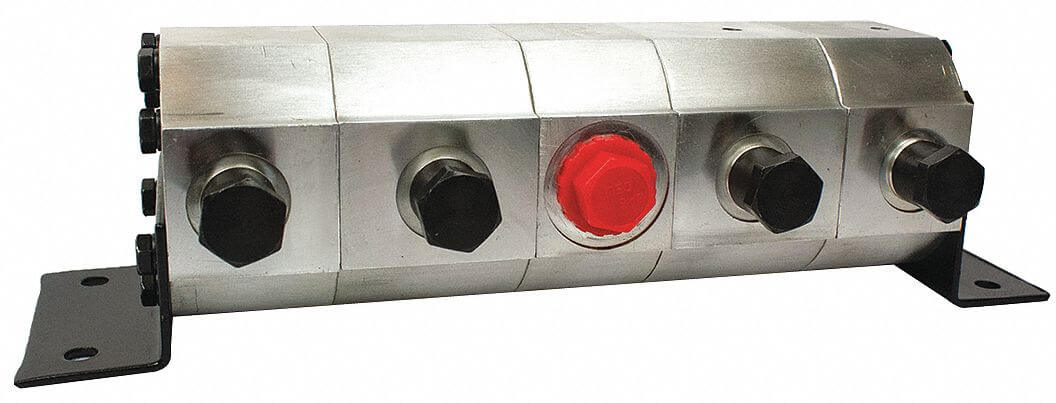

GRESEN Hydraulic Flow Divider, Cast Iron, 5.51 Inch Length, 1.87 Inch Width

| Model | Item | Price (ex. VAT) | |

|---|---|---|---|

| PDC-12-50 | CT7GLH | €257.91 |

Hydraulic Flow Dividers

Hydraulic flow dividers distribute the flow coming from a single pump, equally or in pre-defined ratios, amongst 2 or more actuators. Raptor Supplies offers a wide range of hydraulic flow dividers from Chief and Haldex. These rotary gear type flow dividers are used to synchronise 2 parallel motions hydraulically rather than mechanically. They feature permanently moulded cast iron construction capable of withstanding operating pressure up to 3000 PSI and an integral differential relief valve for reducing built-up pressure inside. The 11 tooth hardened steel gears can rotate at a maximum speed of 4500 RPM, delivering an outer liquid pressure of 4500 PSI. Choose from a wide range of hydraulic flow dividers, available in 2.4 to 5, 2.5 to 5, 5 to 10 and 10 to 20 GPM flow ratings.

Frequently Asked Questions

How are hydraulic flow dividers installed?

- Determine the flow rate requirements for each outlet.

- Choose the appropriate type of flow divider for your application.

- Mount the flow divider securely in the hydraulic system, aligning the ports.

- Connect the hydraulic lines using appropriate fittings and hoses.

- Test the flow divider to ensure even flow distribution and make adjustments if necessary.

- Regularly monitor and maintain the flow divider and hydraulic system for optimal performance.

How do I choose the correct hydraulic flow divider for my hydraulic system?

- Determine required flow rates and choose a divider that can handle them.

- Choose a divider with the correct number of outlets.

- Ensure the divider can handle the hydraulic system's maximum operating pressure.

- Choose a more accurate divider if precision is necessary.

- Choose a durable and low-maintenance divider.

- Confirm compatibility with other hydraulic components.

How to clean and maintain hydraulic flow dividers?

- Regularly inspect for damage, leaks or corrosion.

- Keep it clean by wiping it down.

- Ensure clean hydraulic fluid and replace filters regularly.

- Check and maintain lubrication.

Popular Search Queries

Explore More

- KEYSHAFT

- GRK

- PRO WELD

- High Temperature Lead Wire

- Nippers and Nibblers

- Wares and Tray Drying Racks

- Class T Fuses

- Plastic U-Shaped Channel Stock

- K7300 Series, Reinforced Tubing, Shore A: 73 - KURIYAMA

- ZCM1000 Series, Industrial Tape Dispensers - START INTERNATIONAL

- Wall Mount Metal Halide Light Fixture - APPLETON ELECTRIC

- Compression Union Reducers - DIXON

- CP Apron - TURTLESKIN

- 1056 Series Stock Couplings - FERNCO

- Leather Gloves, Cowhide, Premium, Full Finger, Gray - CONDOR

- Rain Poncho Reuseable Rainwear - CONDOR

- 30080 Shelfmax Shelf Bins - AKRO-MILS