tygon

Filter

Pneumatics

Plumbing

Pneumatics Filter

Pneumatics HosesView all

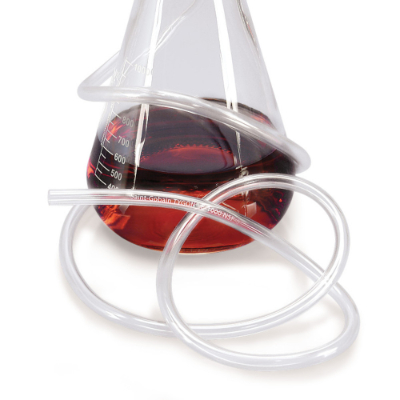

Tubing Transparent, durable, non-porous and chemical- / heat-resistant tubing designed for fluid transportation applications in food, chemical, cosmetic and medical industries. Have with a maximum working pressure of 55 psi and offered in 25- and 50-ft variants

About Tygon

The Tygon catalogue includes tubing, hoses & fittings, adhesive tapes, filtration systems and heat seal equipment. Tygon tubing is ideal for critical fluid transfer and beverage dispensing. These flexible tubes are made of PVC to resist abrasion, wear & corrosion, and provide tensile strengths up to 1800 psi. They offer a maximum hardness of 56 Shore A and can be operated at temperatures ranging from -67 to 165 degrees F.

Major Trade Names

Frequently Asked Questions

Are phthalates dangerous to humans?

They are harmful to the neurological & reproductive systems of human beings, especially children.

What regulatory standards do Tygon S3 units comply with?

They comply with FDA, NSF, 3-A and REACH standards.

What is DEHP?

DEHP is an odourless & colourless organic chemical that is added to plastics for making them flexible.

What is Tygon S3 tubing made of?

Tygon S3 tubing is phthalate-free and is manufactured from a bio-based or NON-DEHP plasticiser.

How do I properly cut Tygon tubing?

- Use a permanent marker or cutter wheel to mark the tubing where the cut needs to be done.

- Clamp the tubing securely in a vice or clamp to prevent it from moving while cutting.

- Use a sharp, clean tubing cutter (specially designed for plastic tubing) and rotate around the tubing, applying gentle pressure.

- Avoid using a blade as it will crush or deform the tubing while making a cut.

- Make sure to keep the cutter wheel aligned with the marked line and rotate the cutter in a single direction until the tubing is fully cut.

- After cutting, remove any burrs from the inside and outside of the edge with the help of a deburring tool or sandpaper.

- Now, clean the cut edge with a dry cloth to remove any dust or debris before making any connection.

Can Tygon tubing be used for high-pressure applications?

Yes, Tygon thermoplastic tubing features a braid reinforcement that helps it to withstand high-pressure applications.

Can Tygon tubing be used in medical applications?

Tygon ND 100-80 tubing is used in the medical industry and is available in five extremely small sizes for varied applications. This tubing is formulated with a higher durometer to offer rigidity, allowing easy handling, yet it is soft enough to reduce problems like kinking and puncturing. It features a clear glass inner bore that aids the visual monitoring when used with intravenous solutions, dialysis and other medical devices.

Popular Search Queries

Explore More

- DUSTLESS TECHNOLOGIES

- MCKINNEY

- SHARPE VALVES

- CORDOVA SAFETY PRODUCTS

- KEYSHAFT

- Insulation Displacement Connectors

- Warning Whip Accessories

- Torque Arms

- Fall Rescue Devices

- Stacking Containers

- 1023 Series Tees - WATTS

- PTFE Chemical and Wear Resistant Sheets - GRAINGER

- KTS-S Series Specialty Fuses - BUSSMANN

- Steel Frame Pedalifts - Four Wheel Winch - WESCO

- 235 Series Horizontal Hold Down Clamps - DESTACO

- Stem Adapters, NPTF Thread, Acetal White - JOHN GUEST

- A Series Explosion Proof Pressure Switches, Watertight 316SS Body - ASHCROFT

- CE Series Industrial Control Transformers, 380, 400, 415V Primary Volts, 110 X 220V Secondary Volts - ACME ELECTRIC

- Tailpiece, Press x Female Union - VIEGA PROPRESS