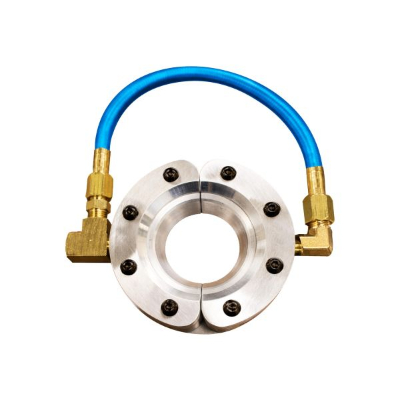

Air Wipe

Exair's Standard Air Wipes feature a 360-degree continuous airstream for blowoff, drying, cleaning and cooling various items, such as pipes, cables, extruded shapes, hoses and similar objects. They further feature a split design that allows quick and easy clamping around the surface of the workpiece pushing through it. These units consist of stainless steel hardware for resisting corrosion.